The use of portable X-ray fluorescence has become routine for gold explorers in recent years, can you explain how it is had been adopted?

The industry-wide take-up of portable X-ray fluorescence has been truly remarkable over the past 10 years. The technology was originally born out of the alloy and scrap metal testing industry, and it was then identified that it could be effectively applied to environmental site monitoring, in particular, contaminated land and remediation work. The use of portable XRF in soil science spurred the natural segue into mineral exploration, and recent developments in sensitivity (limits of detection), speed of analysis, and rugged instruments has revolutionized the way geoscientists conduct real-time in situ and on-site investigations.

Traditionally, mineral exploration is centred on large-scale, routine geochemical sampling where samples are selected, excavated, or drilled and then submitted to a laboratory that is often far away or even in another country. These logistics combined with long lab turnaround times, time-consuming sample preparation, and complex analytical techniques meant that geologists could be waiting many weeks or months to get information back from the field. The use of portable XRF has vastly improved this feedback loop by providing real-time sample information in the field, which can then be used to drive and refine exploration programs on the hop. This is particularly useful for pre-screening and prioritizing samples, expediting significant samples to the lab, and reducing the amount of barren or waste-rock analysis.

Figure 1. Olympus portable XRF devices being used for gold exploration

I believe that portable XRF is not that suitable for direct gold analysis in terms of sensitivity? So how is it then being used to drive gold exploration programmes?

Correct, modern geochemical techniques for gold often target gold at extremely low levels, generally at parts-per-billion (ppb) and even down to parts-per-trillion (ppt) in waters and specifically targeted resistate minerals. Portable XRF has a lower limit of detection (LOD) in the order of 2–5 parts-per-million (ppm) and thus not sensitive enough for use in most exploration regimes. Portable XRF also suffers from interferences with some more common elements such as arsenic, tungsten, and zinc, which can cause false positive results or conceal gold detection. As such we often discourage our clients from even adding gold to their analyzers in order to eliminate confusion and false positive reporting.

The other fundamental issue with direct gold analysis is sample heterogeneity where gold distribution is often extremely irregular and “nuggety” in rocks, rendering it extremely difficult to locate and quantify with confidence. The term finding a “needle in a haystack” is often applied to gold analysis and can only be mitigated through the collection of large samples and the use of good sample preparation to provide homogeneous gold distribution for final analysis.

Where portable XRF is really adding value is in the use for chasing what are called “pathfinder” or “indicator” elements in addition to litho-geochemistry or chemo-stratigraphy. All of the major gold mining companies, as well as most middle-tier and juniors explorers, are now applying the technology routinely in this way.

So what are these “pathfinder” or “indicator” elements, and how are they used to locate gold deposits? Can you also provide an example?

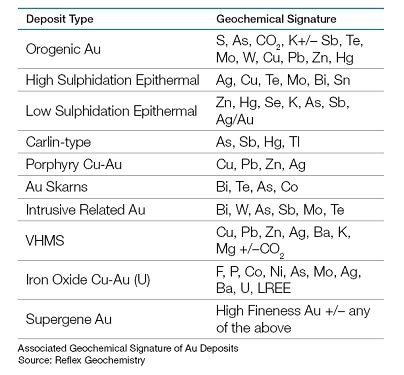

Gold deposits form due to the complex interaction between structures in the ground and mineralised “gold-bearing” solutions, and they form in a large variety of different settings and ages of rocks around the world. A pathfinder or indicator element is one that is intimately related to the style of gold deposit that a company may be looking for. Typical elements can include arsenic, copper, silver, antimony, and potassium and are often referred to as “geochemical signatures” and contain elevated levels of these elements that can be detected by portable XRF. Another positive of these geochemical signatures is that they are quite often present at a scale much larger than that of the gold deposit itself, so they can make the footprint of the target much, much bigger and, hence, easier to explore for. Table 1 (below) contains a summary of the common geochemical signatures associated with several well know styles of gold deposits.

Table 1. Geochemical signatures associated with gold deposits

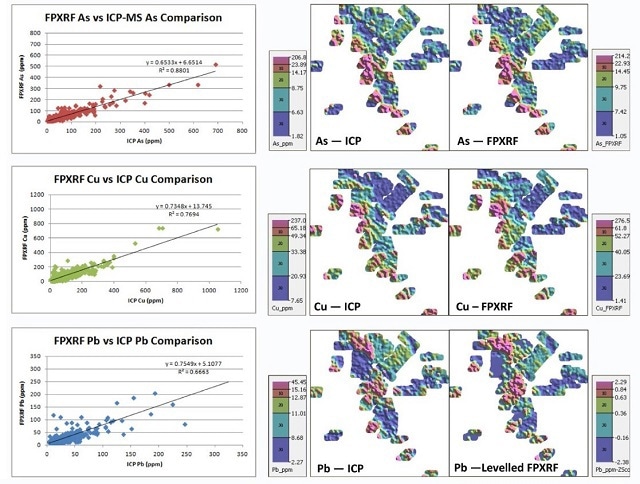

In the example below, a company working in northern Canada used arsenic, copper, and zinc in soil samples as pathfinders to explore for a gold deposit. The charts on the left show the positive correlation between portable XRF and routine laboratory analysis while the geochemical maps on the right show the same result derived from both the portable XRF and lab analysis. This shows the true advantage of being able to generate this type of data in real-time, in the field with XRF.

Figure 2. Contour plots of As, Cu, and Pb in surface soil using field XRF compared with ICP analysis from a Au exploration project in Canada. Images from Arne et al. 2014.[i]

You also mentioned the use of “litho-geochemistry” or “chemo-stratigraphy”? What are these techniques, and how are gold explorers using these with portable XRF?

“Litho-geochemistry” or “chemo-stratigraphy” is the understanding of the chemical components that make up a lithology (rock) and can be used to determine the type of rock, alteration, and order in which the rocks have formed, also termed stratigraphy. This becomes a very useful tool, particularly when geologists have a hard time identifying, deciding, or agreeing on what a particular rock type is. This results when the grain size is too small for visual identification or when the rock has undergone severe deformation due to weathering, alteration, or metamorphism where heat and pressure had changed the rocks.

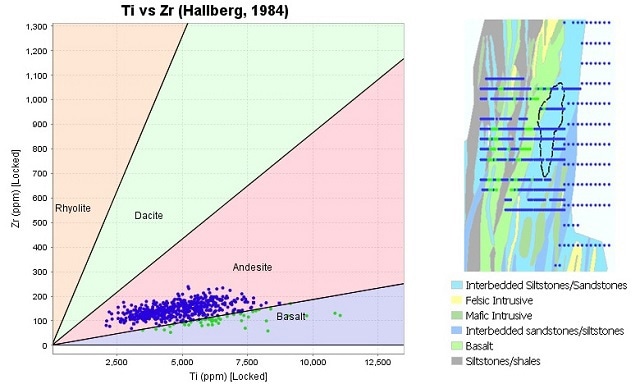

As portable XRF can easily measure many of the key rock-forming elements (Mg, Al, Si, K, Ca, Fe…etc.) as well as many of the trace elements (Cu, Ti, Zr, Sr, Rb, Y, Nb …etc.) it can be used for litho-geochemical determination. By using simple rock classification diagrams (Figure 2, below), XRF data can be plotted, classified, and then used to predict rock types. Gold explorers have used this successfully, particularly in high weathered terrains when the rocks are too difficult to log visually. Additionally, this technique has been used within gold mines to determine the stratigraphy and, in turn, target areas where the gold exists and where future exploration should be prioritised.

Figure 3. An example of applying a rock classification diagram to portable XRF data to map out rock types in Western Africa. Image from Benn et al. 2011.

So what kind of samples do gold explorers typically apply these techniques to, and at what stage in the exploration process is portable XRF most valuable?

Pretty much everything and anything! It all depends on the stage of exploration and the objective of the individual programme. I have seen it applied from the day the geologist first sets foot on a project; this can be in the form of rock chip mapping of outcrops or soil and regolith mapping in weathered terrains. As the projects progress, it can be applied to various drilling campaigns including percussion, reverse circulation, and even directly on diamond drill core. At the mature, in-mine stage we even see it applied to trenching and directly on active mining faces in open pits as well as in underground development exposures. The main things to consider when planning the sampling strategy with portable XRF are what are the objectives and are the techniques fit-for-purpose?

The true value of using portable XRF comes in the form of accelerated information generation and lowering analytical costs. Companies can react quicker and make better decisions about where and when to conduct activities, as well as when to stop or decide that enough work has been done. The ability to fast-track decisions can vastly accelerate projects and ultimately lead to faster discovery. We have seen a lot of this in recent times in West Africa during the recent “gold boom” when gold prices moved above US$1500/ounce and companies were scrambling to favorable locations: an old-school “gold rush” of sorts!

How much money can a company save in one season using a portable XRF?

It all depends on how much work a company is conducting, but it’s not uncommon to see a case where millions of dollars have been saved in a season. We have had clients that are drilling up to 40,000 m of RC drilling in a year and analysing all of it in the field with two portable XRF devices. From this, they may only choose to send say 10,000 m to the lab, as they are not interested in analysing all 40,000 m. Including logistics, sample preparation, and laboratory assay techniques, this may equate to $50+ a sample. So saving 30,000 m at $50/sample can equate to over $1.5 million, for less than a $100,000 upfront investment in their two portable XRF instruments.

How easy is it to operate a portable XRF, and is it still important to have a trained exploration geologist on site?

Portable XRF devices, like most technology, have become very intuitive and easy to use. They are basically a point-and-shoot device where the operator selects the sample and places the instrument directly upon it, or they can opt to use a test stand or workstation where the sample can be sat in place. As portable XRF’s are low-level radiation emitting devices, most countries and states do have legislation and licencing requirements. These are usually pretty straightforward and require the user to take our manufacturer specific training, pay a fee, and, in some instances, take an exam. We have a lot of experience in this area and assist our clients in obtaining whatever measures are necessary to get them up and running quickly.

Yes, it is still extremely important to have a well-trained geologist supervising the operation of any geochemical sampling program, as at the end of the day the data needs to be well collected, processed, and interpreted. The most important training aspect with portable XRF is selecting the right sample and performing appropriate sample preparation to enhance the results. Geologists are very used to conducting these studies, usually termed “orientation studies” or baseline geochemical surveys. During this process, the geologist will validate the sampling techniques, which elements to use, test times, and calibration refinement to ensure they are generating both accurate and precise results. Often this is where a company can come unstuck if they cut corners, but the technique has evolved significantly over the past few years and some great research work has been conducted and published. This is also very relevant to publishing portable XRF data. The industry bodies responsible for reporting standards and conduct have come up with guidelines and examples to assist companies with getting this right.

Could you explain a little about your work on real-time mineral analysis technologies and its association with the Mars Curiosity rover?

Olympus’ involvement and link to NASA’s Mars rover Curiosity comes by way of our portable X-ray diffraction devices. The technology utilised in our TERRA and BTX XRD systems is the same as what has been deployed to Mars on Curiosity to perform mineral identification. This differs from portable XRF in that XRD is used to determine the crystal structure of a mineral which, in turn, defines the chemical compound that the mineral is derived of. A good example is looking at iron ores, where iron can be present in the mineral magnetite, hematite, and goethite and are related to the oxidation state of iron on formation. XRF can only tell us how much iron and other elements are present, whereas XRD can tell us if the mineral is magnetite, hematite, or goethite. This becomes particularly important for mineral processing and extractive metallurgy once the mined materials need to be refined. This can also be very useful to gold explorers, as gold deposits typically have complex mineralogy, and XRD can be used to better define controls on mineralisation.

The other “cool” link to the Mars rover is the ruggedness and engineering of the sensor payload. Many of NASA’s key requirements for the rover are well aligned with remote fieldwork in harsh operating conditions and are synonymous with exploration and mining. These include low power consumption, hot working environments, dusty and wet conditions, and the need for high availability and uptime with low downtime combined with reduced or zero servicing requirements. These have become hallmarks of Olympus’ analytical instruments and set us up well in the minerals industry.

Do you see any significant changes coming in the near future with regards to gold exploration?

Low-level, in situ, real-time gold analysis is the pinnacle of the analytical requirements in our industry and has been for some time. As such, we remain focused on working with key mining companies, industry-leading researchers, and collaborators around the globe in this endeavor. There is a lot of excitement and energy developing in this area, and we hope that we can be involved in a major breakthrough in this area in the near future. As with all analytical instruments, the key drivers continue to be the faster identifications at lower concentrations, a lower price, and the ability to analyze samples in situ and in real-time.

About Aaron Baensch

Aaron is the Principal Geologist – International Mining Group for Olympus Scientific Solutions America’s and is based in Sydney, Australia. He has been working with Olympus (and formerly Innov-X Systems INC.) since 2008. Aaron has become an Industry specialist in the application of field portable x-ray fluorescence (pXRF) & x-ray diffraction (pXRD) analyzers for mineral exploration, mining, mineral processing & environmental markets. He is currently focused on the development of real-time mineral analysis technologies, including the adaption of systems used by NASA on the Mars Curiosity Rover for terrestrial mineral analysis. He is also involved in all aspects of product development, research & development, global business development and key account management.

Aaron is a qualified Geologist with over 15 years’ experience, spanning analytical products, consulting, mining operations & mineral exploration. He is a graduate of the Western Australian School of Mines (WASM), Curtin University - Kalgoorlie and holds a Bachelor of Science in Mineral Exploration & Mining Geology, with 1st Class Honours. Prior to joining Olympus, Aaron spent time with Barrick Gold, Mincor Resources, Straits Resources and Breakaway Resources working in a variety of management and operational roles, throughout Australia & Canada in various gold, nickel and copper deposits. Aaron is also a Member of the AusIMM, AIG, SEG, AAG & the WASM Graduates Association.

Aaron is also a qualified snowboard instructor and when not working, you can find him hitting up the slopes in the USA, Canada & Australia, as well as wake boarding, fishing & kayaking with his family in the summer time.

[1] Arne, Dennis C., Rob A. Mackie, and Stacie A. Jones. “The use of property-scale portable X-ray fluorescence data in gold exploration: advantages and limitations.” Geochemistry: Exploration, Environment, Analysis 14, no. 3 (2014): 233–244.

[1] Benn, Chris, Neil Jones, Kiril Mugerman, James Bell, and David Weeks. “Lithological discrimination in deeply weathered terrains using multielement geochemistry: an example from the Yanfolia Gold Project, SW Mali.” 25th International Applied Geochemistry Symposium, Finland, 2011.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.