Image Credit: mariolav/Shutterstock.com

Over the past decade, the face of mining has transformed drastically, moving from relying on outdated methodologies to implementing new technology to help streamline operations, making them more profitable as well as more environmentally friendly.

Tribology Supporting the Development of Mining Technologies

Most shallow-depth ore bodies have already been mined, leaving the deep and ultra-deep bodies left to be exploited; these deeper bodies require more sophisticated technology. The discipline of tribology is being implemented in a range of mining activities to facilitate the development of these new technologies.

The impact of tribology extends across the entire range of mining and extractive activities that take place during mining operations. Rather than just being limited to addressing the lubrication of moving parts, as is what often first comes to mind when considering tribology, the discipline draws in experts from many areas of science and is concerned with the principles of friction, wear, lubrication, and the design of bearings. These aspects are integrated into mining activities, from exploration, mining/digging and defining, to processing, and delivering the end product.

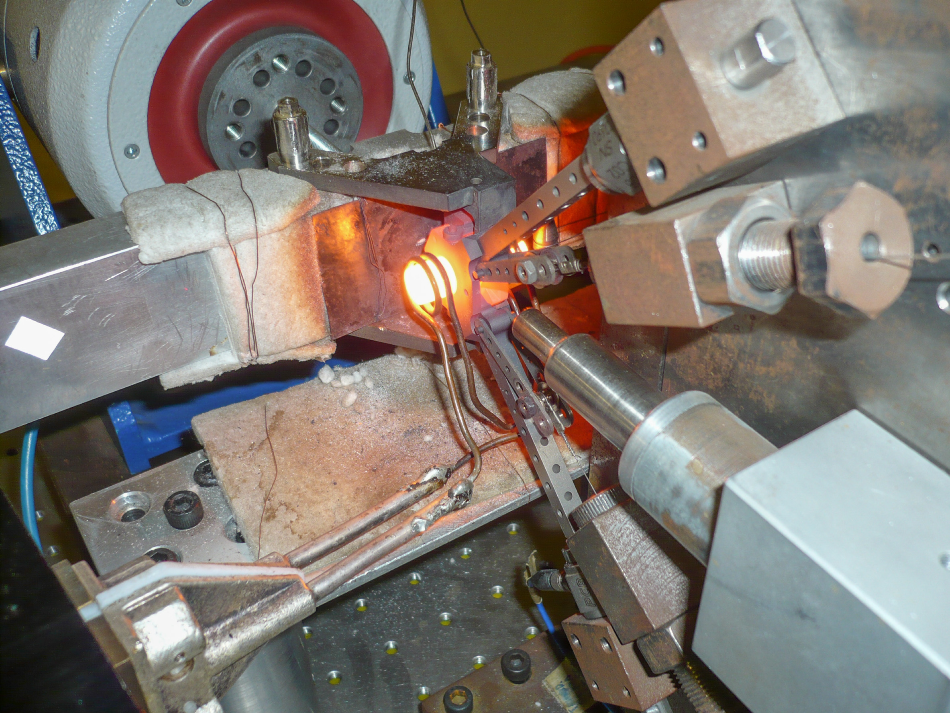

Mining relies on a whole range of equipment, from diamond-tipped saws and rock cutters to rock drills, shovels, loaders, and more. These tools are specifically designed for their purpose and need to be optimized to move the earth, rock, or ore efficiently to expose and draw out the targeted mineral.

Across these activities is one constant, that the tools and surfaces in each process are moving relative to each other, and are therefore subject to wear, friction, and eventually, to becoming less efficient for the task in hand. This problem necessitates tribology, the use of which can resolve these problems and keep tools working optimally, keeping mining processes working efficiently, reducing unscheduled downtime, and therefore increasing productivity and profitability.

In addition, tribology is also used to solve problems in waste management that are becoming growing issues in mining. With the increasing emphasis on protecting the environment, mining is being subject to stricter regulations to prevent its processes, which are generally very impactful to the environment, from being detrimental to the area surrounding the mining site. So, the moving of waste, slurries, and ore by trucks, conveyors, chutes, skips, ore passes, pipelines, and more, are also a key focus for tribology.

Finally, essential utilities like heating and cooling systems, water, electricity, and air, also all call on tribology to be optimized in mining operations.

Building an Interdisciplinary Team to Optimize Processes

While at first glance, it is hard to see how tribology fits into mining, other than being used for the lubrication of the moving parts of the tools involved in mining. However, the discipline is essential to optimizing all aspects of operations, resulting in increased profitability and productivity of a project. Successful operations, therefore, are beginning to recruit professionals across disciplines who can advise on tribological processes, such as mechanical, electrical, mining, or civil engineers, as well as metallurgists, design drafting technicians, and more, who can work together to develop the best tribological practices for individual mining projects.

Advancements in tribology represent the largest step forward that mining companies are making in terms of updating their processes, integrating new technologies, and hiring new talent. The mining sector has long been considered to be falling behind when it comes to embracing new technology when compared to other industries, and for years little has been done to help it catch up.

However, mining companies have recently begun facing new pressures, such as tighter regulations to protect the environment and to limit fossil fuel use to reduce carbon emissions. This has led to a surge of activity with mining companies to become more innovative and open to new technologies to help them comply with improved regulations.

References and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.