The ZEN AI Toolkit, inclulding ZEN Intellesis and ZEN Image Analysis modules, provides ZEISS microscopes with machine-learning image segmentation and classification using image analysis and object measurements.

The modules deliver automated minerals identification, classification, measurement, and quantification. They are available for use with ZEISS light microscopes, from the operator-driven Axiolab 5 to the fully automated Axioscan 7 Geo.

Automated Sample Analysis

Light microscopes are used on a daily basis for evaluating mining samples during the exploration of new resources and to assess the performance of the recovery process.

Operators must conduct a rigorous and precise evaluation of samples, a labor-intensive task that consumes a significant amount of time during the day.

Using ZEN Intellesis and ZEN Image Analysis, mineralogy classification and measurement are performed automatically, allowing the operator to focus on data interpretation and other vital tasks.

When combined with ZEN Image Analysis, ZEN Intellesis offers state-of-the-art machine learning, which is trainable on-site, for object classification and measurement. This helps to differentiate mineralogy, resulting in improved time to results and efficiency.

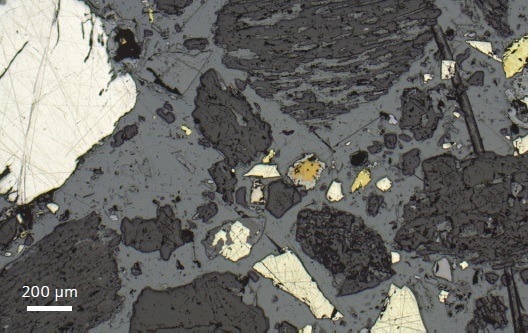

Figure 1. Reflected light image acquired with ZEISS Axiolab 5. Sample of milled copper ore mounted in a resin block and previously prepared for SEM analysis. Remnants of a carbon coating remain on some surfaces. Image Credit: ZEISS Natural Resources

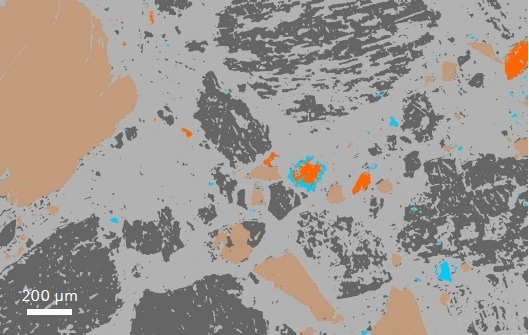

Figure 2. Artificial color map following Intellesis classification. Despite the challenges presented by sample preparation, e.g., the impossibility of obtaining a transmitted light image, surface scratches, and gauges, Intellesis automatically classifies the individual constituents of this image. Resin in light grey, gangue in dark grey, pyrite in brown, chalcopyrite in orange, and chalcocite in blue. Image Credit: ZEISS Natural Resources

Consistent Sample Evaluation

Quality monitoring is a continual process dependent on data being fed into an information loop from which operational decisions are made. This enables strategic planning using the evidence gathered over a period of time.

Reliable, consistent data is crucial. Unlike human operators, the ZEN Intellesis and Image Analysis modules do not suffer fatigue on long days and promise consistent results after each sample.

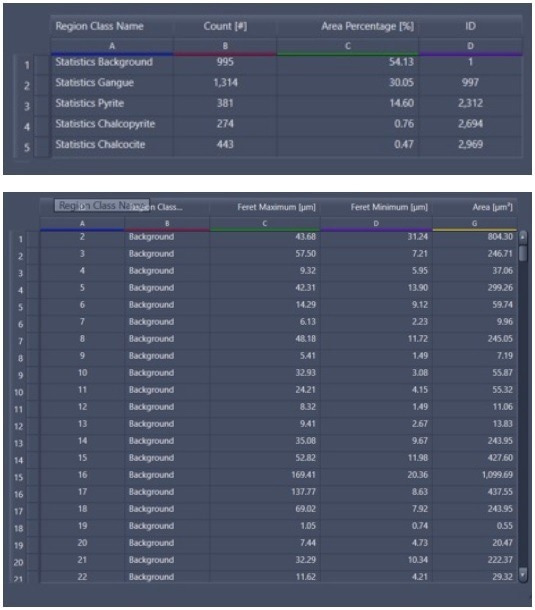

Figure 3. Following classification, the Image Analysis module automatically measures the individual constituents and provides statistical information, including modal distribution, size, area, perimeter, etc, as well as the modal proportion of phases present. Image Credit: ZEISS Natural Resources

Flexibility in Application

Flexibility and ease of use are key factors when using the ZEN modules. Machine learning models can be trained at the local level without needing to consult artificial intelligence (AI) experts. They can also be updated and refined over time, offering greater flexibility for materials classification.

Images from any ZEISS microscope can be processed, offering all levels of operation ranging from operator-driven image capture with Axiolab 5 to complete automation with Axioscan 7 Geo.

The wealth of information that can be leveraged using the fully automated Axioscan 7 Geo lends itself to a detailed and comprehensive analysis of the sample matter. Axioscan 7 Geo can capture images using various contrast methods and numerous angles of polarization, offering a high density of pixel information that can be evaluated and interpreted by artificial intelligence (AI) methods.

After implementation of Intellesis segmentation and image analysis, the results can be analyzed further with the application of the Petrography Analysis Toolbox (PetPAT). PetPAT is able to access the wealth of data the Axioscan 7 Geo images capture to provide outputs, including the angle of extinction relative to the analyzer, grain orientation, grain size distribution, the position of grain boundaries, and textural information.

Image Credit: ZEISS Natural Resources

This information has been sourced, reviewed and adapted from materials provided by ZEISS Natural Resources.

For more information on this source, please visit ZEISS Natural Resources.