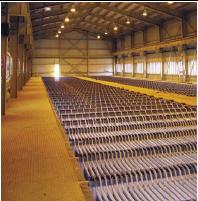

At a copper refinery located in Piedras Verdes, Mexico, Strongwell’s fiberglass operating platforms and walkways totaling over 10,000 square feet were installed to withstand corrosion. The refinery employs solvent extraction electrowinning (SXEW) process for copper extraction from the ore. The process involves the use of an electrolyte liquid, which is highly corrosive to steel and aluminum. Hence, corrosion resistant FRP structural platforms, handrails and grating were chosen for the project.

Benefits of FRP over Steel and Aluminum

The FRP platforms have high durability when compared to steel and aluminum and their low electrical conductivity ensures the safety of workers. Moreover, the installation of FRP handrail, grating and shapes was much easier and faster thanks to their light weight.

FRP platforms are the ideal solution for use in corrosive operating environments such as SXEW process used in copper refineries. This makes fiberglass the material of choice for such kind of operations.

Technical Data

| Product |

: |

Platform and Walkway System |

| Process |

: |

Pultrusion, Open Molding |

| Materials |

: |

EXTREN Series 625 fiberglass reinforced polyester; 2" DURAGRATE V.E. molded grating; SAFRAIL handrail system |

| Sizes |

: |

EXTREN structural shapes and plate used: 8" x 3/8", 10" x 1/2" channels; 2" x 1/4", 3" x 1/4"; 4" x 1/2" angles; 10" x 5" x 3/8", 8" x 4" x 1/2" I-beams; 10" x 10" x 1/2" wide flange beam 1/2" plate |

| For |

: |

Piedras Verdes, Mexico copper refinery |

About Strongwell

Strongwell Corporation is involved in the design, fabrication and testing of molded or pultruded fiber reinforced polymer composite products for construction, commercial and industrial applications.

Strongwell has been pultruding fiber reinforced polymer composite structural products since 1956. Today, with more than 65 pultrusion machines and 647,000 square feet of manufacturing space in three plant locations, Strongwell has unequaled capacity, versatility and flexibility to meet the needs of its customers and allied partners. All Strongwell pultruded products are made in the USA. Click here to learn how Strongwell’s pultruded products out perform traditional materials.

The company is financially strong, quality oriented, technically advanced, and customer focused. Strongwell's customers include Fortune 500 industrial and commercial firms, major architectural and engineering firms, leading contractors and distributors, and many other companies - both large and small - in a variety of markets.

This information has been sourced, reviewed and adapted from materials provided by Strongwell Corporation.

For more information on this source, please visit Strongwell Corporation.