Gold (Au) is able to be easily formed into a variety of shapes (such as thin sheets and wires or intricate shapes), can conduct electricity and is resistant to corrosion, a unique combination of characteristics that make it one of the most useful metals on earth, besides one of the most precious.

The versatility of this material means that it is often used in wide-ranging uses, from ornamental decorations, jewelry and artwork to aerospace, machine/dentistry, electronics and currency.1

Not all uses of gold require the same purities, and the price of the material is highly dependent on its level of impurity. In order to address this, ASTM has developed B562-95: Standard Specification for Refined Gold, which are specifications for various purities of refined gold.2

This article uses the levels specified in ASTM B562-95 as a guideline to analyze the impurities in gold with ICP-OES. Due to its speed of analysis, minimal maintenance requirements and low cost of operation, the Avio® 500 ICP-OES was chosen to do this work.

The machine uses less argon than comparable machines, meaning it has a much lower cost per analysis, thanks to the Avio 500's Flat Plate™ plasma technology. Due to its PlasmaShear™ technology, the Avio 500 can handle a high level of dissolved solids running over long periods of time.

The PlasmaShear™ technology creates exceptional stability in difficult matrices with no maintenance required by using a thin stream of air to cut off the top of the plasma; this eliminates deposition on the interface window.

The Avio 500 has an advanced optical system that is able to conduct simultaneous analysis and has a faster sample-to-sample time with excellent accuracy and stability.

Experimental

Samples

To simulate digestion diluted 100 times, all analyses were performed in a 1% gold solution in 10% HCl.

Table 1 shows how 1% gold solution was spiked with the elements at their specified levels for 99.99% and 99.995% gold in order to determine accuracy. Please note that ASTM method B562-95 does not specify either nickel (Ni) or arsenic (As) in 99.995% gold.

Table 1. ASTM Method B562-95 Specifications for Impurities in Gold and Associated Concentrations in Solution with 100 x Dilution. Source: PerkinElmer

| Element |

99.99% Gold |

99.995% Gold |

Specification

(wt%) |

Concentration in 1% Solution

(mg/L) |

Specification

(wt%) |

Concentration in 1% Solution

(mg/L) |

| Ag |

0.009 |

0.9 |

0.001 |

0.1 |

| As |

0.003 |

0.3 |

--- |

--- |

| Bi |

0.002 |

0.2 |

0.001 |

0.1 |

| Cr |

0.0003 |

0.03 |

0.0003 |

0.03 |

| Cu |

0.005 |

0.5 |

0.001 |

0.1 |

| Fe |

0.002 |

0.2 |

0.001 |

0.1 |

| Mg |

0.003 |

0.3 |

0.001 |

0.1 |

| Mn |

0.0003 |

0.03 |

0.0003 |

0.03 |

| Ni |

0.0003 |

0.03 |

--- |

--- |

| Pb |

0.002 |

0.2 |

0.001 |

0.1 |

| Pd |

0.005 |

0.5 |

0.001 |

0.1 |

| Si |

0.005 |

0.5 |

0.001 |

0.1 |

| Sn |

0.001 |

0.1 |

0.001 |

0.1 |

Table 1 also shows the associated concentrations in solution. External calibration curves prepared in 8% aqua regia at 0.5, 1 and 1.5 times the specified concentrations were compared to all measurements. An internal standard, yttrium (Y), was added to all samples and calibration standards.

Instrumentation

Using the wavelengths in Table 3 and the parameters in Table 2, the Avio 500 ICP-OES was used to perform all analyses. A standard torch position of -4 was used, as well as the standard sample introduction components.

Table 2. Avio 500 ICP-OES Instrumental Parameters. Source: PerkinElmer

| Parameter |

Value |

| Nebulizer |

MEINHARD® K-1 |

| Spray Chamber |

Baffled Glass Cyclonic |

| RF Power |

1500 W |

| Injector |

2.0 mm Ceramic |

| Plasma Flow |

8 L/min |

| Auxiliary Flow |

0.2 L/min |

| Nebulizer Flow |

0.7 L/min |

| Torch Position |

-4 |

| Sample Uptake Rate |

1 mL/min |

| Replicates |

2 |

| Plasma View |

Axial |

| Read Time Range |

Min = 1 sec; Max = 5 sec |

Table 3. Wavelengths. Source: PerkinElmer

| Element |

Wavelength (nm) |

| Ag |

328.068 |

| As |

188.979 |

| Bi |

223.061 |

| Cr |

205.560 |

| Cu |

327.393 |

| Fe |

259.939 |

| Mg |

285.213 |

| Mn |

259.372 |

| Ni |

341.476 |

| Pb |

220.353 |

| Pd |

340.458 |

| Si |

251.611 |

| Sn |

189.927 |

| Y (int std) |

371.029 |

The application can be optimized for robustness and sensitivity because of the ability to adjust torch position.

Interference-free wavelengths were selected. However, spectral interference from gold was removed from As 188.979 nm using Multicomponent Spectral Fitting (MSF)3 within Syngistix™ software; the Avio 200 hybrid-scanning ICP-OES can also accomplish this analysis.

Significant savings with regard to argon use was achieved by combining the simultaneous and rapid analysis of the Avio 500 with a total argon consumption of only 9 L/min. This means that there is a lower cost of analysis per sample.

Results and Discussion

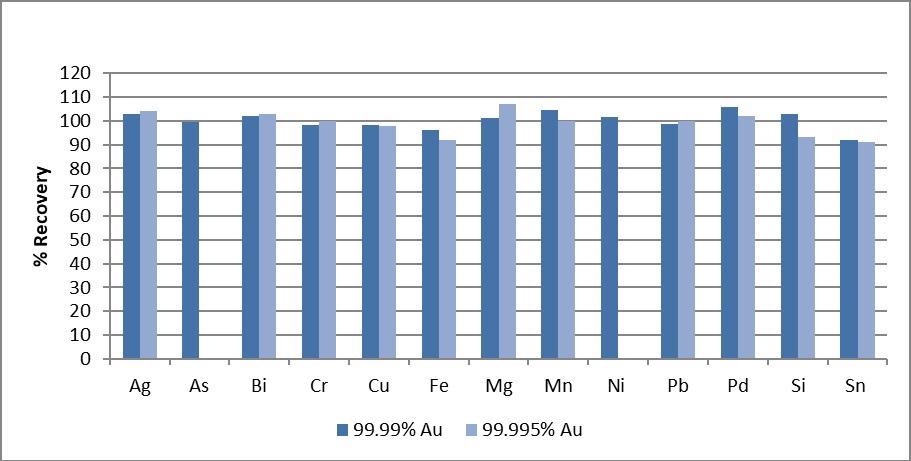

In order to determine accuracy, external calibration curves were measured against 1% gold solutions that were spiked at the specification levels for 99.99% and 99.995% gold.

The spike recoveries at both levels of specification are shown in Figure 1. Accuracy is shown with all recoveries in 10%.

Figure 1. Analyte spike recoveries in 1% Au at the 99.99% (dark blue) and 99.995% (light blue) impurity specification levels. Image Credit: PerkinElmer

This demonstrates that one 1% gold matrix does not inhibit impurity analysis with proper analytical conditions and selection of wavelengths.

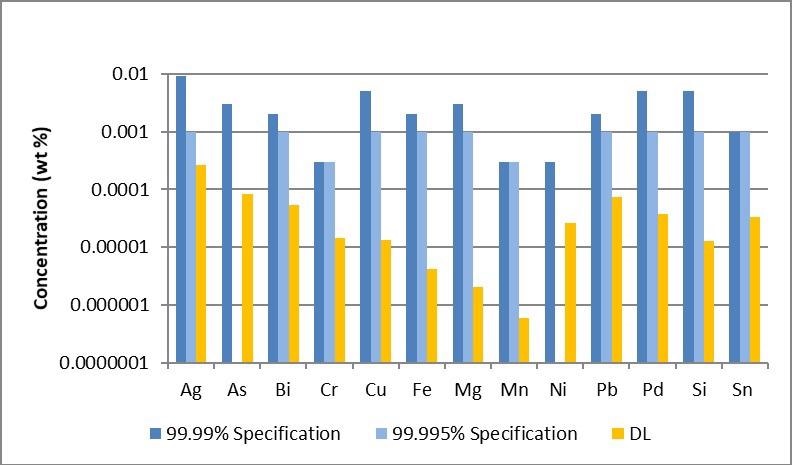

An unspiked 1% Au solution was measured seven consecutive times and compared to a calibration curve in order to determine the detection limits in 1% Au. Then, the measured concentration’s standard deviation was multiplied by 3.14.

The orange bars in Figure 2 show the resulting detection limits – they are at least magnitude lower, though mostly two orders of magnitude lower, than the specification limits. This demonstrates that even lower concentrations than those specified in ASTM B562-95 could possibly be measured.

Figure 2. Analyte detection limits (orange bars) in 1% gold plotted alongside the ASTM method B562-95 impurity specifications for 99.99% Au (dark blue) and 99.995% Au (light blue). Image Credit: PerkinElmer

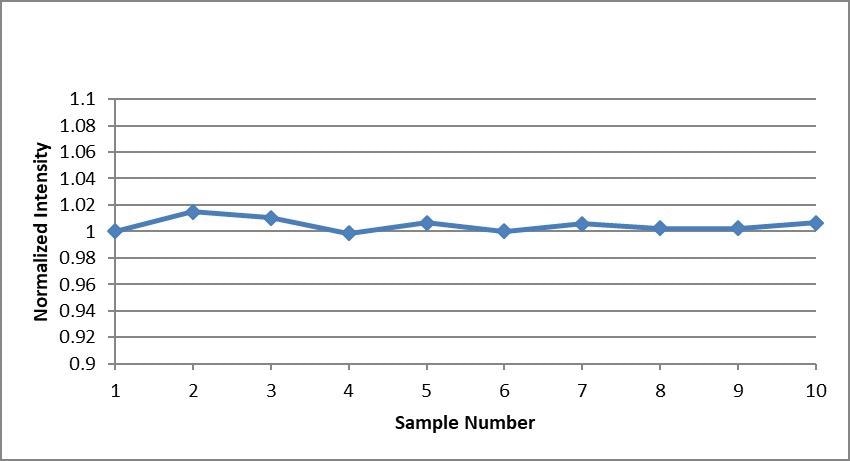

The final step was for ten consecutive analyses of a 1% Au solution to be monitored for the internal standard signal in order to assess stability.

Figure 3 illustrates the stability, showing signal variations of less than 2%. This demonstrates the Avio 500 ICP-OES’s exceptional system stability and no matrix effects.

Figure 3. Internal standard signal over 10 analyses of a 1% Au solution. All signals were normalized to the first sample. Image Credit: PerkinElmer

Conclusion

The impurities in gold specified in ASTM method B562-95 at 99.99% and 99.995% purity levels can be successfully measured by the Avio 500 ICP-OES, as demonstrated in this article.

Standard Avio 500 instrument conditions were used to accomplish these analyses. As required, Multicomponent Spectral Fitting was used to select proper wavelengths and overcome matrix-induced spectral interferences.

No matrix-induced instrument drift and low level analyte analysis were allowed by this combination. It was also indicated that it might be possible to measure even lower impurity levels due to the detection limits of 1-2 orders of magnitude lower than the specification limits.

References

1. https://geology.com/minerals/gold/uses-of-gold.shtml.

2. ASTM Method B562-95: “Standard Specification for Refined Gold”, 2012.

3. “Multicomponent Spectral Fitting”, PerkinElmer Technical Note, 2016.

Consumables Used

Table 4. Source: PerkinElmer

| Component |

Part Number |

| Sample Uptake Tubing, Black/Black (0.76 mm id), PVC |

N0777043 (Flared)

09908587 (Non-Flared) |

| Drain Tubing, Gray/Gray (1.3 mm id), Santoprene |

N0777444 |

| Arsenic Standard, 1000 mg/L |

N9300180 (125 mL)

N9300102 (500 mL) |

| Bismuth Standard, 1000 mg/L |

N9303761 (125 mL)

N9300105 (500 mL) |

| Chromium Standard, 1000 mg/L |

N9300173 (125 mL)

N9300112 (500 mL) |

| Copper Standard, 1000 mg/L |

N9300183 (125 mL)

N9300114 (500 mL) |

| Iron Standard, 1000 mg/L |

N9303771 (125 mL)

N9300126 (500 mL) |

| Lead Standard, 1000 mg/L |

N9300175 (125 mL)

N9300128 (500 mL) |

| Magnesium Standard, 1000 mg/L |

N9300179 (125 mL)

N9300131 (500 mL) |

| Manganese Standard, 1000 mg/L |

N9303783 (125 mL)

N9300132 (500 mL) |

| Nickel Standard, 1000 mg/L |

N9300177 (125 mL)

N9300136 (500 mL) |

| Palladium Standard, 1000 mg/L |

N9303789 (125 mL)

N9300138 (500 mL) |

| Silicon Standard, 1000 mg/L |

N9303799 (125 mL)

N9300150 (500 mL) |

| Silver Standard, 1000 mg/L |

N9300171 (125 mL)

N9300151 (500 mL) |

| Tin Standard, 1000 mg/L |

N9303801 (125 mL)

N9300161 (500 mL) |

| Yttrium Standard, 1000 mg/L |

N9303810 (125 mL)

N9300167 (500 mL) |

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.