Sweden’s Kaunis Iron Mine represents the latest facility in one of the country’s most prominent industries. This prestigious new mine brought in Degerfors Laboratory (D-LAB) to support its iron analysis work.

The iron ore had to be dried prior to analysis commencing, with moisture levels determined to ensure these would not impact the analysis.

Image Credit: LECO Corporation

D-LAB faced throughput issues as part of this process because its current moisture determination methods used a manual balance that could only accommodate one sample at a time. This method also required the attention of a technician every five minutes, causing further delays.

As it was necessary to employ the ISO 3087:2020 method, a single run could take over 5 hours to complete.

Image Credit: LECO Corporation

D-LAB contacted LECO, who were able to provide a solution: the TGM800 thermogravimetric analyzer.

This system facilitates the determination of moisture content via a mass-loss-on-drying technique - a technique that sees a sample’s mass loss measured as a function of oven temperature and drying time.

Using the TGM800, up to 16 samples can be simultaneously analyzed in a single run. This instrument offered a significant improvement over the manual moisture balance on this basis alone.

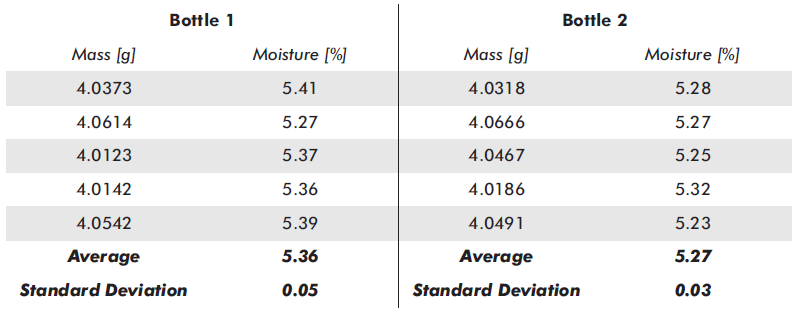

D-LAB wanted to test the TGM800 prior to adopting this, and the lab sent iron ore samples to the LECO labs in St. Joseph, Michigan, and Berlin, Germany. Two bottles of iron ore samples were run using the TGM800 as 1 g and 4 g samples.

Source: LECO Corporation

The results were compared and found to be consistent, not only between the first and second bottles but also between the 1 g and 4 g samples. It was also noted that results and standard deviation acquired via the TGM800 matched results acquired via the manual moisture balance.

Most notably, the TGM800 successfully analyzed 16 samples simultaneously in runs that took between 20 and 25 minutes - including sample preparation time.

The option to consistently ensure reliable results while delivering 16x sample throughput in a fraction of the original time was sufficient motivation for D-LAB to purchase a TGM800, which now handles 30,000 samples per year.

D-LAB is also considering acquiring a second instrument to meet its increasing analysis demands. The lab has retained its manual moisture balance as a backup instrument, but the TGM800’s 100% uptime has meant that the manual balance has never had to be used.

LECO is delighted with the success of the TGM800, and the company is looking forward to continuing working in partnership with D-LAB over the coming years.

This information has been sourced, reviewed and adapted from materials provided by LECO Corporation.

For more information on this source, please visit LECO Corporation.