Elemental analysis by XRF is essential during mining and processing operations to monitor and control the limestone composition. EDXRF provides excellent performance for measuring carbonates and major oxides in limestone.

Limestone and Its Applications

Limestone (calcium carbonate) has many uses as the main ingredient in cement and mortar and is used as an aggregate in concrete and asphalt for building roads. Limestone is also used as a soil conditioner and is the raw material for making quicklime (calcium oxide) and slaked lime (calcium hydroxide).

The Importance of Monitoring and Controlling Limestone Composition

During mining and processing operations it is important to monitor and control the limestone composition to ensure the proper quality and characteristics desired for the various products. Rigaku meets this industry need with a high-performance, low-cost benchtop EDXRF system.

Instrumentation

Rugged and reliable, the NEX QC+ is an ideal tool for measuring major carbonate and oxide components in limestone, with simple and intuitive software designed for the non-technical, at-line operator and for use in quality control labs. This article demonstrates the measurement of CaCO3, MgCO3, Fe2O3, Al2O3, SiO2, and K2O in high calcium limestone using empirical calibration.

Figure 1. Rigaku NEX QC+ XRF spectrometer. Image Credit: Applied Rigaku Technologies, Inc.

- Model: Rigaku NEX QC+

- X-Ray tube: 4 W Ag-anode

- Detector: SDD

- Sample type: Hydraulically pressed pellets

- Film: Polypropylene 4 µm

- Environment: Helium

- Analysis time: 450 seconds total

- Optional: 6-position automatic sample changer

Sample Preparation

A sample is first ground to a homogeneous powder, approximately 100 – 200 mesh, and dried to remove excess moisture. Limestone is somewhat hygroscopic, and carbonates give limestone a pseudo-crystalline nature, so sample preparation for EDXRF is done by making a hydraulically pressed pellet using a wax binder.

To prepare a pressed pellet, 6.0 g of powder is homogeneously mixed with 0.6 g of wax binder (such as Chemplex® SpectroBlend® powder or tablets), and the resulting mix of sample and binder is pressed in a hydraulic press using 20 tons of pressure. This creates a pellet that minimizes mineralogical effects and creates a stable sample for analysis. Use the same recipe of binder and powder for all calibration standards and unknown samples.

Calibration

A set of 14 assayed site-specific standards were provided by an industry user for this demonstration. Regression fits are made using alpha corrections that automatically compensate for variations in X-Ray absorption and enhancement effects within the sample.

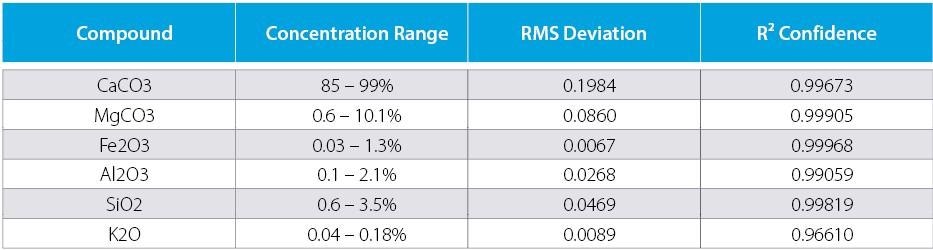

Table 1. Summary of measurements of limestone standards.

Image credit: Applied Rigaku Technologies, Inc.

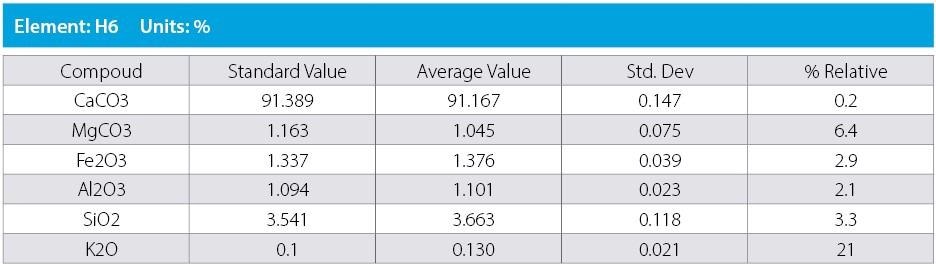

Repeatability (Precision)

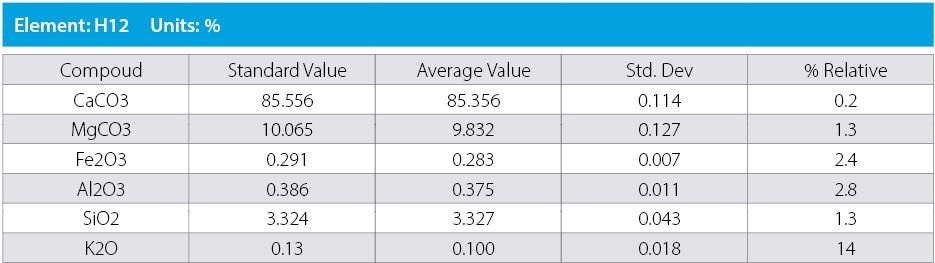

Typical precision is shown below. Ten repeat analyses of each sample were performed with the sample in static position using a total analysis time of 450 seconds per analysis.

Table 2. Demonstration of measurement repeatability for limestone standard H12.

Image credit: Applied Rigaku Technologies, Inc.

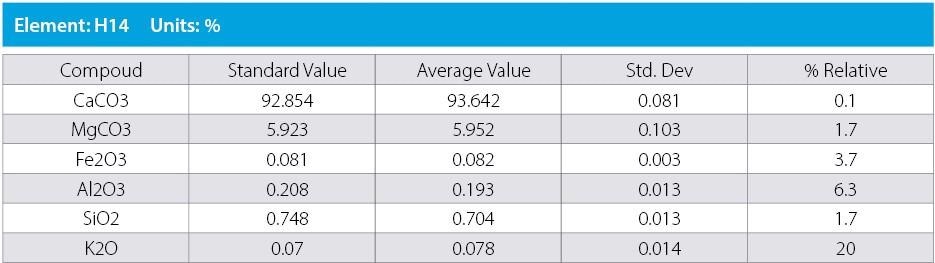

Table 3. Demonstration of measurement repeatability for limestone standard H14.

Image credit: Applied Rigaku Technologies, Inc.

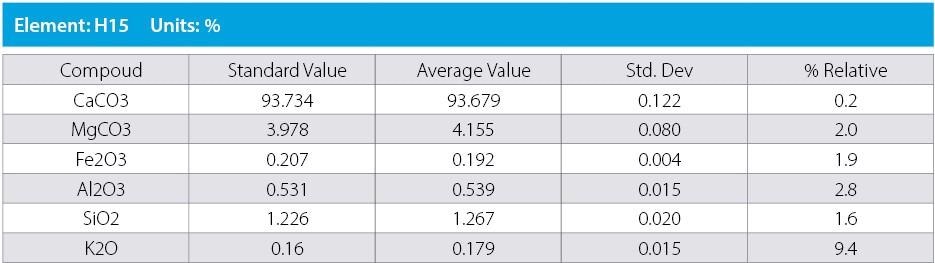

Table 4. Demonstration of measurement repeatability for limestone standard H15.

Image credit: Applied Rigaku Technologies, Inc.

Table 5. Demonstration of measurement repeatability for limestone standard H6.

Image credit: Applied Rigaku Technologies, Inc.

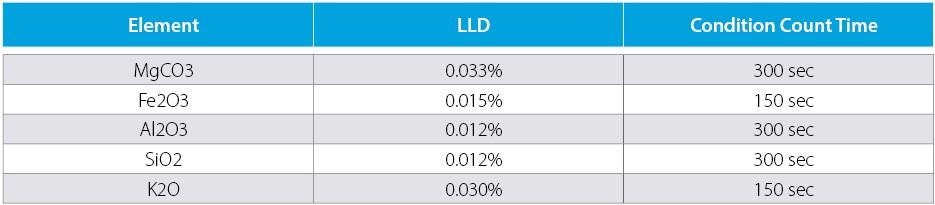

Detection Limits

The empirical method was used to determine detection limits. In the empirical method, ten repeat analyses of a blank sample (boric acid prepared as a pressed pellet) are taken with the sample in static position, and the standard deviation is determined.

The lower limit of detection (LLD) is then defined as three times the standard deviation. Typical LLDs are shown below. Detection limits depend on several factors, including analysis time, the overall composition of the limestone, and calibration concentration ranges.

Typical LLD 450 seconds Total Analysis Time:

Table 6. Empirically determined lower limits of detections (LLD).

Image credit: Applied Rigaku Technologies, Inc.

LLDs shown are typical and may differ depending on measurement time used and the overall elemental composition of the sample being tested.

Conclusion

The performance demonstrated in this article confers that the NEX QC+ provides excellent sensitivity and performance for the measurement of carbonates and major oxides in limestone. Self-contained with simple touchscreen operation, NEX QC+ is a cost-effective and excellent tool for at-line control and quality checks throughout the mining and processing.

Chemplex and SpectroBlend are registered trademarks of Chemplex Industries, Inc.

This information has been sourced, reviewed, and adapted from materials provided by Rigaku Corporation.

For more information on this source, please visit Rigaku Corporation.