Recovering gold and other valuable metals from used ore materials can be a profitable recovery venture. Rigaku NEX DE gives a superior measurement of trace valuable metals in various used ore materials.

In the processing of ores, the desired metals and other base metals are extracted, leaving mostly silicates, minerals, and other base ore materials. Gold and other precious metals can be recovered by further processing and extraction of the ore material from used ore dumps or old tailing piles.

To screen and measure the gold content, the NEX DE EDXRF system with a high-throughput SDD detector gives a superior measurement of trace valuable metals in various used ore materials. This article demonstrates the measurement of gold, and also shows the recovery of uranium in used ore material.

Figure 1: Rigaku NEX DE XRF spectrometer. Image credit: Applied Rigaku Technologies, Inc.

Instrumentation

- Model: Rigaku NEX DE

- X-Ray tube: 12 W 60 kV Ag-anode

- Detector: High-throughput SDD, 500,000+ cps

- Film: Polypropylene 4 µm (Mylar® 6 µm also suitable)

- Analysis time: 400 seconds

- Environment: Air

- Sample tray: 15-position Autosampler

- Options: Manual Compaction Press

Sample Preparation

A sample is prepared by grinding the material to a dry, homogeneous medium powder of approximately 200 mesh (~75 µm particle size). Simply fill a sample cup with powder and compact using a Rigaku Manual Compaction Press.

Calibration

Since a high degree of accuracy is desired in the industry, the empirical regression calibration method is used. An empirical calibration was built using a set of 12 commercially available standards from AMIS (African Mineral Standards) that model used ore materials.

Using the empirical approach, an overlap correction was employed to automatically compensate for the spectral overlap of the Zn-Kβ line on the Au-Lα line. Appropriate alpha corrections were enabled to compensate for various absorption/enhancement matrix effects. A summary of the two empirical calibrations is shown in the following sections.

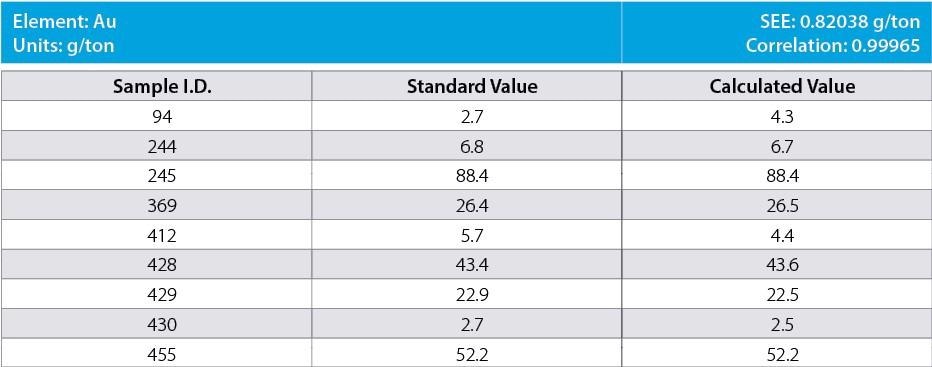

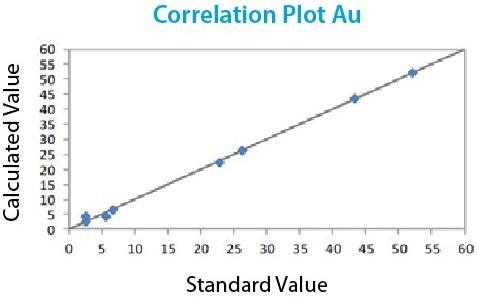

Gold Calibration

Table 1. Gold calibration measurements.

Image credit: Applied Rigaku Technologies, Inc.

Figure 2. Gold calibration. Image credit: Applied Rigaku Technologies, Inc.

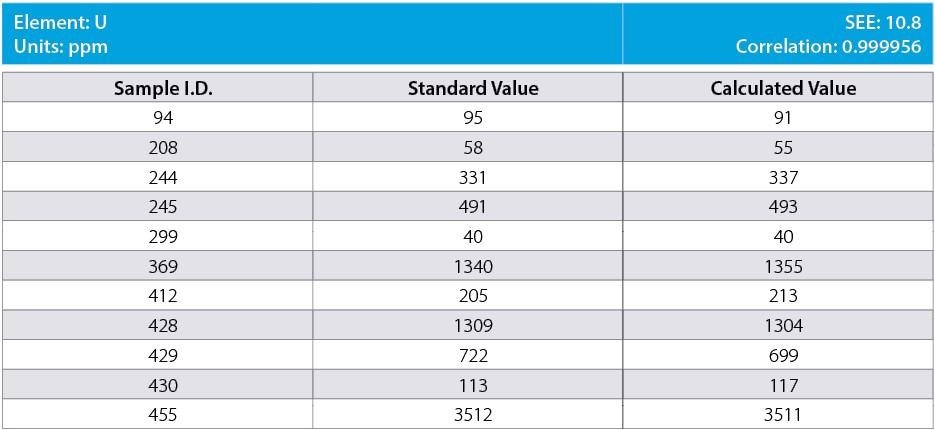

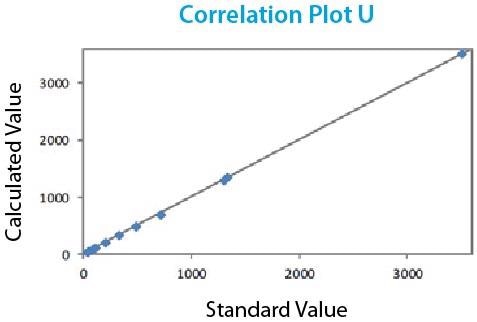

Uranium Calibration

Table 2. Uranium calibration measurements.

Image credit: Applied Rigaku Technologies, Inc.

Figure 3. Uranium calibration. Image credit: Applied Rigaku Technologies, Inc.

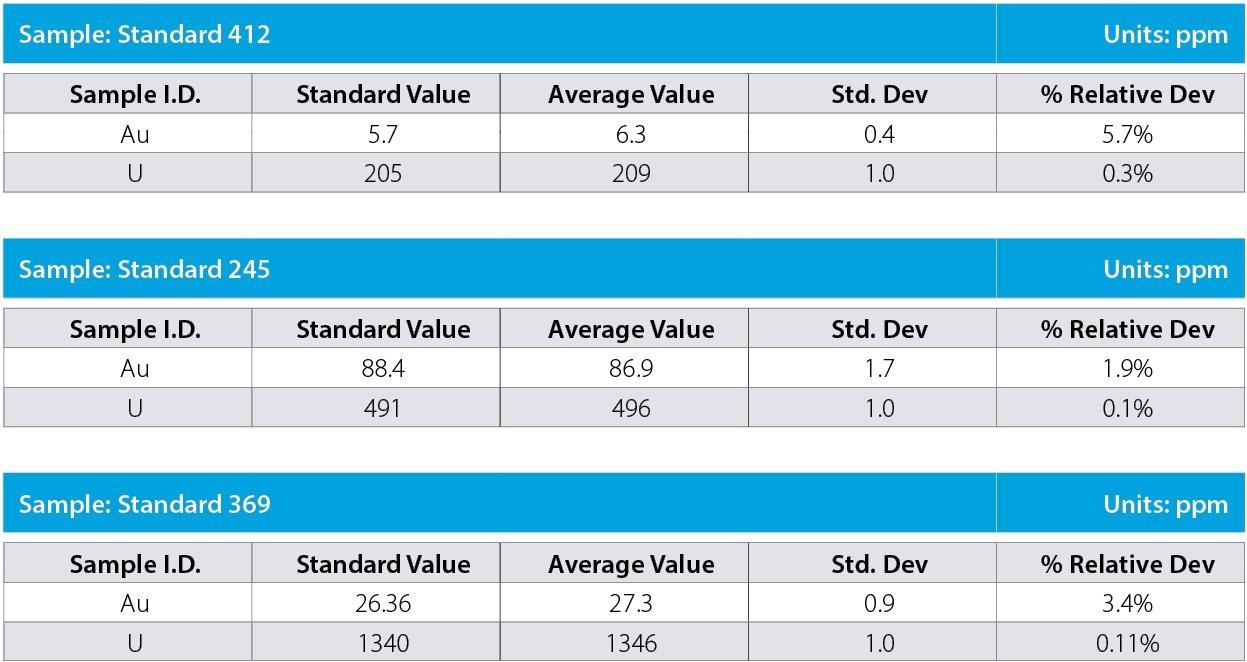

Repeatability (Precision)

To demonstrate the repeatability and recovery of the measurement, three standards were each measured 10 times in static position. The average results and standard deviations are shown below.

Table 3. Repeatability demonstration for gold and uranium.

Image credit: Applied Rigaku Technologies, Inc.

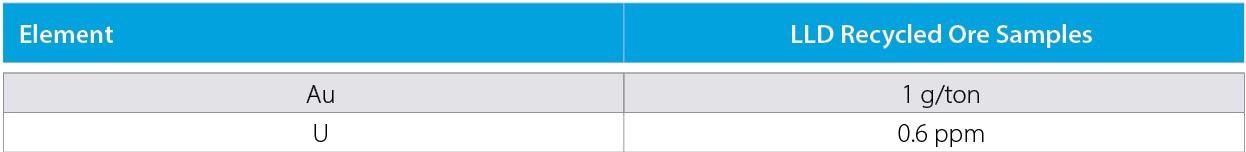

Detection Limits

In the empirical method, ten repeat analyses of a blank powder sample (boric acid, Chemplex® SpectroBlend®, or other appropriate blank powder) are taken with the sample in static position, and the standard deviation (σ) is determined. The LLD (lower limit of detection) is then defined as 3σ. The total measurement time for the LLDs shown below is 400 seconds per analysis.

Table 4. Lower limits of detection for gold and uranium.

Image credit: Applied Rigaku Technologies, Inc.

LLDs shown are typical and may differ depending on measurement time used and the overall elemental composition of the sample being tested.

Detection limits are dependent on many factors, including measurement time, background removal, detector throughput, sample preparation, and calibration concentration range. For example, optimum detection limits can be achieved using longer analysis time, calibrating only over a low concentration range.

Conclusion

The NEX DE offers analysts and technicians a simple yet powerful and versatile system for quantifying elemental composition. The results of this study indicate that given matrix-matched calibration and proper sampling, the Rigaku NEX DE can achieve excellent results for monitoring and measuring the concentration of gold and other valuable elements such as uranium in the recovery of used ore materials.

Chemplex and SpectroBlend are registered trademarks of Chemplex Industries, Inc.

Mylar is a registered trademark of E.I. du Pont de Nemours and Company and its affiliates.

This information has been sourced, reviewed, and adapted from materials provided by Rigaku Corporation.

For more information on this source, please visit Rigaku Corporation.