Zinc (Zn) is the fourth most-used metal in the world today, after iron (Fe), aluminum (Al), and copper (Cu). Approximately 50 % of global Zn production is used annually to protect steel (galvanized steel), brass, and Zn alloys from corrosion.

Zn is also used in construction materials, infrastructure projects, and automotive manufacturing. Every car uses around 18 kg (40 lbs) of Zn.1 The demand for Zn across these industries means that there is a continuous need for exploration and mining activities.

The primary source of Zn ore is sphalerite (ZnS), which accounts for 95 % of the global supply. This offers numerous opportunities to capitalize on by-products because other elements, such as lead (Pb), present as galenite, Cu, present as chalcopyrite, and silver (Ag), are also associated with sphalerite.

Application

Accurately determining concentrations of Zn, Pb, Cu, and Ag during the exploration process is important to ascertain the viability of deposits. These measurements are equally important in the mining process itself, as they help provide grade control of the extracted ores while separating useful ore from waste.

The long lead times associated with lab analysis can limit progress and productivity in both settings. Geologists and mining companies must be able to perform analyses rapidly to optimize exploration strategies, locate suitable drilling targets, and ensure that recovered ore meets appropriate grade and quality requirements.

From a practical perspective, this need for rapid, efficient analysis necessitates on-site geochemical analysis that offers comparable quality to lab analysis while maintaining appropriately low detection limits and high accuracy when detecting the elements described here.

Handheld X-ray fluorescence (XRF) spectrometry represents an effective, efficient means of on-site analysis that offers real-time measurement of Zn, Pb, Cu, and Ag concentrations, allowing users to make confident decisions throughout the mining process.

Handheld XRF Analysis

The Thermo Scientific™ Niton™ XL5 Plus handheld XRF analyzer (Figure 1a) represents the lightest, most compact tube-based handheld XRF analyzer currently on the market.

The instrument boasts a 5 w/50 kV miniaturized X-ray tube coupled with a large area silicon drift detector and graphene window. These robust features allow the Niton XL5 Plus analyzer to deliver accurate elemental analysis with unparalleled efficiency at each step of mining and exploration.

The XL5 Plus analyzer’s Mining Mode allows users to measure 41 elements from magnesium (Mg) to uranium (U) using up to four different filters and voltages. This allows the signal-to-noise ratios of fluorescence lines to be enhanced across the entire range of energy.

Mining Mode leverages a powerful, proprietary fundamental parameter-based algorithm to account for the high variability of sample composition. This algorithm effectively corrects for absorption and secondary excitation effects that arise from the matrix, ensuring accurate results. Results are shown on the analyzer’s screen in real-time (Figure 1b).

Users can optimize Mining Mode settings as required and then store these under Profiles to maintain multiple analytical methods on a single instrument. With a range of profiles in place, the most appropriate can be selected for a given task to perform the required measurements efficiently.

The Niton XL5 Plus analyzer also features an integrated GPS, enabling spatial data visualization using GIS programs. This feature is extremely useful for mapping and site modeling.

Method

Using a handheld XRF analyzer, Zn-Pb-Cu-Ag ores can be analyzed in two ways: either in “point-and-shoot” mode directly at the rock face or after sample preparation.

The handheld XRF analyzer’s “point-and-shoot” mode is well-suited to screening. Its capacity to deliver qualitative or semi-quantitative results makes it ideal for the rapid localization of high-grade ore.

Sample preparation is necessary to obtain accurate quantitative results. A sample should be collected and homogenized using a grinder. Drying may also be necessary if the sample’s moisture level is high.

Once prepared, the resulting powder is introduced into a sample cup before undertaking analysis using the XL5 Mini Test Stand (Figure 1c). Preparing samples in this way enables longer measurements and typically yields results comparable to those of laboratory methods.

In this study, Zn-Pb-Cu-Ag ore samples were finely ground and packed into standard XRF sample cups fitted with 4 µm polypropylene film. These samples were measured for 90 seconds using Mining Mode on the Niton XL5 Plus analyzer. Three beam conditions were used: 30 seconds/Main Range, 30 seconds/High Range, and 30 seconds/Light Range.

A simple post-calibration adjustment was made to optimize accuracy. This was completed by running various reference materials with a concentration range and mineralogy similar to the unknown samples.

Figure 1. a) Niton XL5 Plus analyzer; b) Display of results for elemental analysis of Zn-Pb-Cu-Ag ore; c) Sample analysis using the Thermo Scientific™ XL5 Mini Test Stand. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

Results

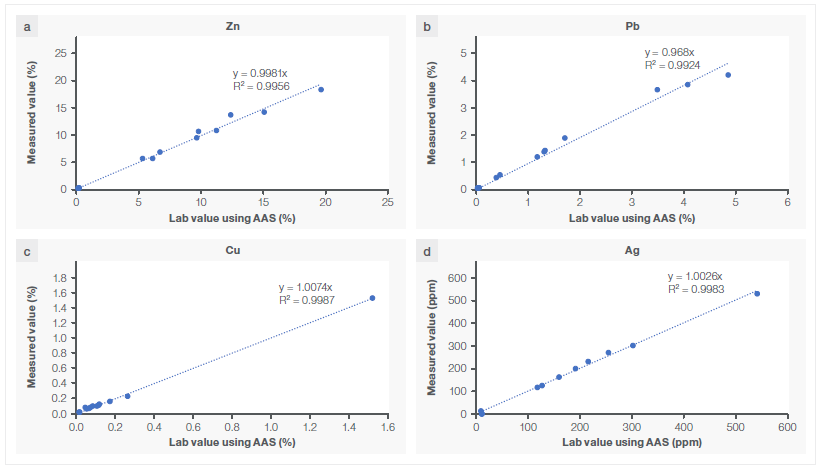

The results from the analysis of 13 samples using the Niton XL5 Plus analyzer were then plotted against lab results acquired using atomic absorption spectrometry after total sample dissolution.

The correlation coefficient (R2) measures how closely data sets correlate with one another, with a perfect correlation possessing an R2 of 1. When the slope of the curve is close to 1, this also indicates a low systematic error.

There was found to be a high correlation and low systematic error between field and lab results (Figure 2). This result showcases the high accuracy of the handheld XRF analytical method and its suitability for the exploration and mining of Zn-Pb-Cu-Ag-Ores.

It was also noted that accurate measurement of Ag was possible, present at low concentrations (down to 10 ppm) in the sample. The results for Fe and light elements can provide additional information about the mineralogy of the rocks.

Figure 2. Correlation diagrams of lab vs. field measurements using the Niton XL5 Plus analyzer for a) Zn, b) Pb, c) Cu, and d) Ag. Image Credit: Thermo Fisher Scientific – Handheld Elemental & Radiation Detection

Conclusion

The Niton XL5 Plus analyzer offers excellent portability and sensitivity, making it one of the most powerful and advanced handheld XRF analyzers currently available. This instrument can support geologists and mining operations managers to perform a range of tasks, which features include:

- The capacity to access assay data in real time.

- There is potential to significantly reduce the number of samples that require lab testing.

- Allowing users to make rapid and confident decisions onsite.

- The potential to improve productivity, saving the mining operation time and money.

References and Further Reading

- The World Zinc Factbook 2020, International Lead and Zinc Study Group, https://www.ilzsg.org/

Acknowledgments

Produced from materials originally authored by Thermo Scientific.

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.

For more information on this source, please visit Thermo Fisher Scientific – Handheld Elemental & Radiation Detection.