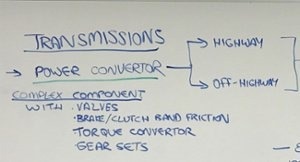

Transmissions are highly complicated systems for the conversion and direction of power from an engine to a drive train or other end applications. Transmissions are usually found on mobile equipment and include gear sets as well as clutch and brake sets, valves, and torque converters. Mobile transmissions are normally divided into two kinds, namely, highway and off highway. Off highway comprises of heavy-duty construction equipment, mining equipment, agricultural equipment, and other mobile equipment that is generally used in places other than on a paved road.

Ask the Expert: Transmission Oil Analysis

Transmissions are a very great consumer of oil and are one of the largest uses of gear sets. In the US, transmissions used 160 million gallons of oil in 2016. This is 7% of the usage of transmission oils across the globe.

Lubricants for transmissions are highly specialized and cautious consideration must be taken to make sure that the correct lubricant is used. Lubricants for transmissions must lubricate the gear sets as well as help in cooling and cleaning the components in the transmission. Therefore, these lubricants must be considerably flexible as they lubricate fixed drives, differentials, and hydraulic systems.

Usually, these lubricants have a relatively low viscosity. These lubricants have several additives for reducing potential varnish formation, anti-oxidants for longevity, and anti-friction modifiers. It is necessary to match the right lubrication to the transmission. Following are the well-known lubricants that are listed by suppliers:

- Ford—Mercon

- Caterpillar—TDTO/FDOA

- General Motors—Dexron

- Allison—TES

The gear sets in transmissions are typically made from clutch bands and tool steels, and torque converters are usually paper-based products for wet clutches and ceramic for dry clutches.

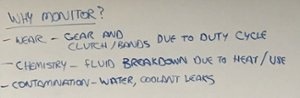

Why Monitor?

- Wear: Excessive wear can specify an impending failure and must be monitored.

- Chemistry: Break down of transmission fluids is largely due to excessive usage or heat.

- Contamination: Common contaminants are sand, water, and dirt. Oftentimes, coolant can reach transmission fluids, specifically in the presence of an intercooler.

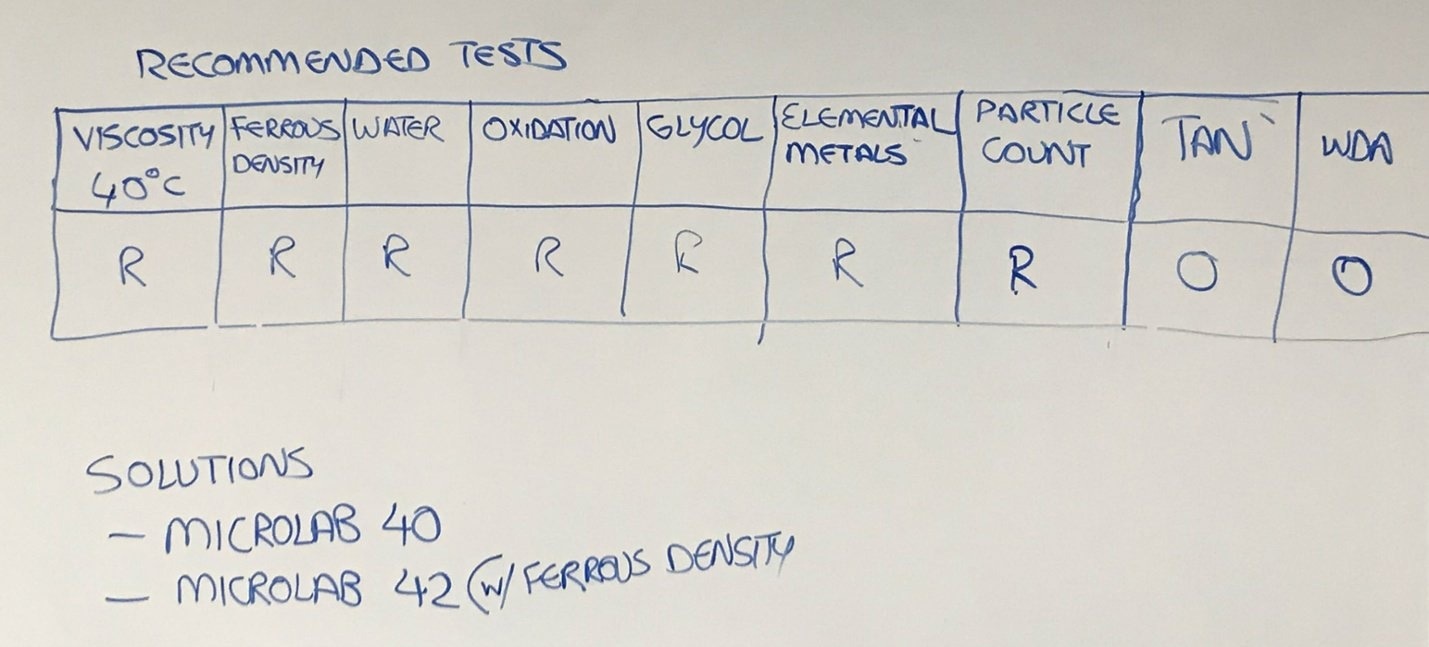

Recommended Tests

Ferrous Wear

Wear in transmissions can normally be observed as a metallic “fuzz” at the bottom of the transmission housing. A certain amount of wear is normal in such a system, but trending ferrous wear helps determine whether abnormal wear has occurred.

Glycol Contamination

Glycol contamination measurement is specifically significant if the transmission system includes an intercooler. Glycol is a quite unpleasant contaminant that can make the oil worthless, consequently causing transmission damage. Glycol is generally measured using elemental spectroscopy or infrared spectroscopy. Elemental spectroscopy usually involves the detection of metallo-organic corrosion inhibitors that are contained in high concentrations in the glycol coolant, but not native to the oil composition. Boron, silicon, potassium, and sodium are generally added to coolant for inhibiting corrosion.

Particle Count

Transmission systems can suffer from non-metallic wear due to sand particles and dirt apart from ferrous or metal wear. If filter systems are not monitored, these wears can clog the filter systems, resulting in premature failure.

Experts normally suggest the use of MicroLab series to monitor transmissions. It is rare that only the transmission oil is monitored. A general usage example would be for monitoring transmission oil, engine oil, and perhaps hydraulic oil. The MicroLab 40 and 42 are perfect solutions for this sort of usage. The MicroLab 42 adds a ferrous wear monitor for tracking and trending ferrous particles.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.