Monitoring turbines through oil analysis is well established and popular. All turbines, steam as well as gas, have a huge oil reservoir for lubricating the turbine bearings. Former designs included separate sumps for the hydraulic control of valves, while the most recent designs may have the hydraulic sump and lube oil connected together. Power plant operators who are new to oil analysis can easily get confused about what all the tests are.

Luckily, the industry has developed umbrella specifications for power plant lubrication monitoring, such as ASTM D4378 and ASTM D6224. Moreover, these specifications define nearly all the tests used to qualify lubricants for new and in-service monitoring for power plants.

ASTM D4378, “Standard Practice for In-Service Monitoring of Mineral Turbine Oils for Steam, Gas, and Combined Cycle Turbines,” concentrates on recommended tests for gas and steam turbines. As per ASTM, the objective of this practice is “to maintain effective lubrication of all components of the turbine and protect against the onset of problems related to oil degradation and contamination.”

ASTM D6224, “Standard Practice for In-Service Monitoring of Lubricating Oil for Auxiliary Power Plant Equipment,” concentrates on auxiliary equipment that supports power-generating turbines. Auxiliary equipment includes components such as hydraulic systems, gears, pumps, diesel engines, electrohydraulic control (EHC) systems, and compressors. The Ask the Expert video tries to condense all this information down to its basics, such as which specific tests one should focus on and what equipment sets enable one to carry out these tests on turbines and supporting equipment.

Ask the Expert: Turbine Oil Analysis

Recommended Tests

Kinematic Viscosity

Kinetic viscosity is defined as the resistance of a fluid to flow under gravity. The most important lubricant physical property is viscosity. Lubricants should have appropriate flow characteristics to assure that a sufficient supply reaches lubricated parts at various operating temperatures. The viscosity of lubricants differs according to their grade or classification, as well as the degree of contamination and oxidation in service.

Oil viscosity is supposed to rise in due course and use, and loss of viscosity is regarded as more serious than an increase. In power plants, viscosity is regularly measured as soon as the oil is changed in order to confirm the right oil was added, and also on a periodic basis. With new technologies, it is easy to measure kinematic viscosity—solvent-free, low-volume systems are available that integrate ease of use with data logging ability.

Total Acid Number

Total acid number refers to a titration technique designed to specify the relative acidity in a lubricant. The acid number is used as a guide to follow the oxidative degeneration of an oil in service and is often mentioned on OEM equipment or lubricant supplier guides that are followed by power plants. Oil changes are usually indicated when the TAN value attains a preset level for a given lubricant and application. A sudden increase in TAN would be an indicator for abnormal operating conditions (for example, overheating) that need investigation.

Water Contamination

The most common liquid contaminant in power plants across the world is water, and it has to be monitored always. Too much water in a system destroys the ability of a lubricant to separate opposing moving parts, enabling severe wear to take place with resulting high frictional heat. Water contamination must be within 0.25% for most equipment, and not greater than 100 ppm for turbine lube and control systems. Several new technologies are available to detect water contamination in lube oils, and on-site results correlate very well with laboratory methods.

Antioxidant Trend

Antioxidant trend is defined as the level of antioxidant additive present. As oxidation products build up, it causes the oil to become degraded, and in most cases, a bit acidic. In case oxidation becomes severe, the lubricant will corrode the critical surfaces of the equipment. Long-life turbine oils include additives that are designed to curb the effects of oxidation such as varnish and sludge. Varnish deposits are still a concern to turbine maintainers working with API Group 2 oils. Color spectrophotometers and simple filters are employed on-site help to determine whether a varnishing situation is occurring.

Particle Counting

Particle counting is the measure of the purity of oil. It is a crucial test for filtered gearboxes, turbines, and hydraulics. This test has developed to be so much more than just a measure of effective filtration. Latest technologies such as LaserNet Fines count particles and report to ISO 4406 or SAE AS 4059 and also offer more information to understand why and where the particles are originating.

Particle imaging allows the power plant maintenance team to instantly find dirt/sand particles and also the level of ferrous debris that contributes to the count. This level of detail allows the development of smarter work orders, devoted to eliminating the root cause of the high counts.

Elemental Spectroscopy

Elemental spectroscopy is a method for detecting and measuring metallic elements in a used oil produced as a result of contamination, additives, and wear. The oil sample is energized to make each element absorb or emit a quantifiable amount of energy, which represents each element’s concentration in the oil. The results reflect the concentration of all dissolved metals (from additive packages) and particulates.

This test is the backbone for all off-site and on-site oil analysis tools because it offers information on the machine, wear condition, and contamination accurately and rapidly. Its main drawback is that its particle detection efficiency is poor for particles with a size of 5 µm or more. Many OEMs report out elemental wear for alarms, so users should make sure that they review the OEM guides for starting points.

Wear Debris Analysis/Analytical Ferrography

Wear debris analysis (WDA) defines either a patch or an analytical method which involves separating magnetic wear particles from the oil and depositing them on a glass slide called ferrogram. Microscopic examination of the patch or slide allows characterization of the wear mode and possible sources of wear in the machine. This method is called analytical ferrography. It is an excellent indicator of abnormal ferrous and non-ferrous wear, but it can generally only be performed by a skilled analyst.

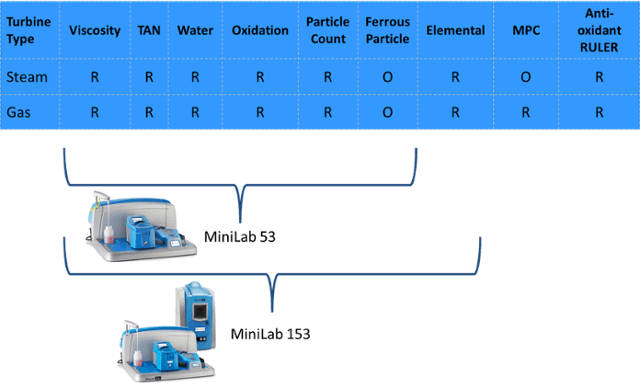

Recommended oil analysis test packages for turbines

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.