Oil analysis is a very beneficial tool for gear systems. Geared systems can be found across both industrial and mobile equipment. Although they are built to be highly reliable, they cause interruption and incur costs when they break or wear because of poor operation or contamination. Oil analysis is an excellent tool to detect when failure conditions are starting to appear, and as such, the majority of gear manufacturers propose condition monitoring, including oil analysis.

Gear wear can be worsened by poor lubrication, misalignment, and contamination. Once the gears reach their operational tolerances, grinding, gear slippage, jamming, or tooth breakage can take place, necessitating replacement or overhaul, which can result in substantial downtime.

Generally speaking, gear drives can be categorized into two classes from a lubrication methodology—pressure-lubricated and splash-lubricated. In splash- or bath-lubricated gearboxes, the lubricant is applied by permitting the gear to function partly submerged in the oil. In pressure-fed systems, oil is taken from the gear case, pumped via a filter, pressure relief valve, heat exchanger, and supplied back to the unit under pressure. Oil is applied to the system using spray nozzles in a manifold. Both types of lubricated system can be observed by oil analysis, though the tests may vary to some extent.

Ask the Expert: Gear Box Oil Analysis

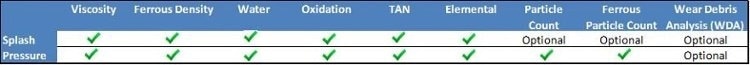

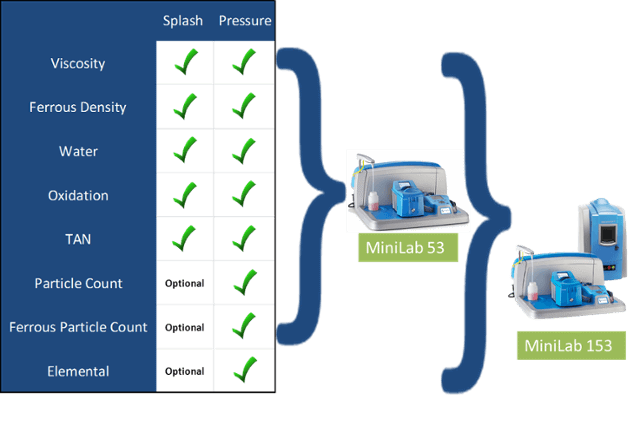

Recommended oil analysis test packages for gear drives

Viscosity

Viscosity can be defined as the resistance of a fluid to flow. Viscosity is the most critical physical property of a lubricant for gear drives. Lubricants must have appropriate flow features to ensure that a sufficient supply of oil reaches lubricated parts at different operating temperatures. The viscosity of lubricants differs based on their grade or classification, in addition to the degree of oxidation and contamination in service. If the viscosity of the lubricant varies by over 10% from nominal grade, a change of oil is usually suggested by the lubricant supplier. Oil viscosity is anticipated to rise over time and use, while a decrease in viscosity is said to be more critical than an increase. Thus, a working alarm range is +20% to −10%, i.e. not more than 20% over nominal, and not less than 10% under nominal grade.

Ferrous Density

Ferrous density can be defined as a measure of the total amount of ferrous magnetic debris present in ppm. Measured using a magnetometer, ferrous debris ranging in size from sub-micron to visible will trigger a change in electrical current relative to the volume of metal present. Trending the volume of total ferrous debris is a chief indicator for any gearbox and should be incorporated into all screening test packages. The actual value in ppm is trended. An increase of 10% in the wear rate specifies an irregular change.

Water

Typically not desirable in oil, water can be detected visually if gross contamination is present (gives a cloudy appearance). Too much water in a system damages a lubricant’s ability to separate opposing moving parts, allowing extreme wear to happen with resulting high frictional heat. Water contamination should not surpass 0.25% for most gear drives, though certain pressurized systems have lower limits.

Oxidation by Infrared Analysis

Infrared spectroscopy is an excellent method for detecting organic contaminants, water, and oil degradation products in a used oil sample. During a lubricant’s service life, oxidation products amass, causing the oil to become tainted and, in most cases, somewhat acidic. If oxidation becomes extreme, the lubricant will corrode the important gear surfaces. When the “oxidation number” is greater, the oxidation present is higher. Conditions such as varnishing, sticky rings, lacquering, sludge deposits, and filter plugging occur in systems with oxidation issues. Infrared spectroscopy also specifies contamination because of glycol antifreeze and free water. Manufacturers have issued rules for oxidation numbers and liquid contaminants, but this is basically a trending tool.

Total Acid Number

Total acid number (TAN) denotes a titration technique meant to specify the relative acidity in a lubricant. The acid number is used as a guide to track the oxidative degeneration of oil in service. Oil changes are repeatedly indicated when the TAN value touches a preset level for a specified lubricant and application. A sudden rise in TAN would be suggestive of irregular operating conditions (for example, overheating) that require analysis. The majority of lubricant suppliers provide TAN condemnation limits in the bulletins. Typically, a rise of 0.5 over the starting value is a cause for concern. One should be always aware of the starting new oil value—it can be higher than anticipated for some gear oils because of the additive packages present.

Particle Count

Particle count is a technique used to count and categorize particulate in a fluid based on accepted size ranges, typically according to ISO 4406 and SAE 4059. This is an extremely helpful test to enhance reliability as reducing particulates in the oil will prolong the gearbox life. It is suggested for pressure-lubricated gears and is said to be optional for bath-lubricated gear systems, since it is pointless in measuring particle count if no filters are available or if there is no plan to filter the oil (using a cart, etc.).

Ferrous Particle Count

Ferrous particle count is a method that quantifies the ferrous debris present based on size and quantity, not based on its concentration. Built-in magnetometers are generally used today to measure events as oil flows via the magnetometer. Direct-read ferrography systems are also used to monitor and assess ferrous wear. These systems are beneficial for understanding the size and quantity of ferrous debris particles and they supplement the spectroscopy and ferrous density methods. These techniques measure the ratio of small and large ferrous particles in the sample. This data may be used to measure the wear particle concentration and the severity indexes and to set alarms when these limits touch a predetermined level.

Elemental Spectroscopy

Elemental spectroscopy is a method for identifying and quantifying metallic elements in a used oil resulting from contamination, wear, and additives. The oil sample is energized to make each element release or absorb a quantifiable amount of energy, which specifies the element concentration in the oil. The results echo the concentration of all dissolved metals (from additive packages) and particulates. This test is the mainstay for all off-site and on-site oil analysis tools, as it provides information on machine, wear condition, and contamination comparatively rapidly and accurately. Its chief limitation is that its particle detection efficiency is weak for particles 5 µm in size or larger, and hence ferrous density must be measured first.

Wear Debris Analysis/Analytical Ferrography

Wear debris analysis (WDA) defines either a patch or an analytical method that isolates magnetic wear particles from the oil and places them on a glass slide called a ferrogram. Microscopic inspection of the slide or patch allows characterization of the wear mode and probable sources of wear in the machine. This method is called analytical ferrography. It is a great indicator of abnormal ferrous and non-ferrous wear; however, it is typically only performed by a skilled analyst.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.