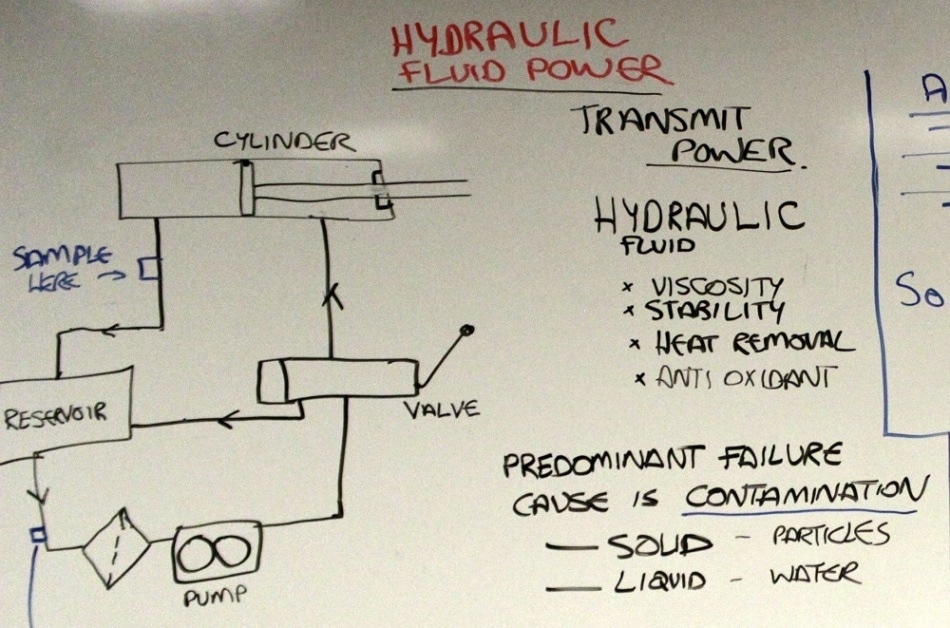

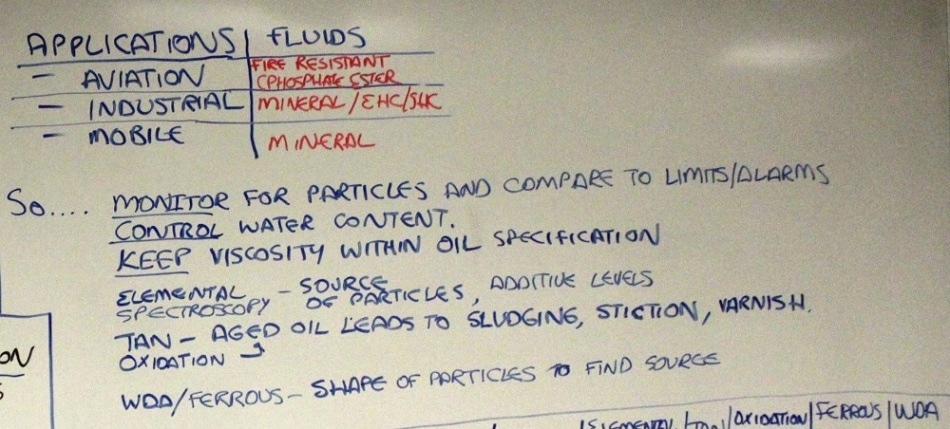

Hydraulic systems are employed in aviation, mobile and industrial applications for transmitting power to run equipment. These systems are unimaginably compact, effective and weightless when compared to a mechanical equivalent. Hydraulic fluids transmit force in the system, and as such are cautiously selected by the system producer. Oxidation resistance, high flash and fire points, chemical stability and viscosity are all evaluated and consequently, synthetic and mineral hydrocarbon fluids are chosen for industrial and mobile systems, while functional chemicals like phosphate esters are selected for specialized industrial and aviation applications.

One can determine the influence of hydraulic fluid on predicted performance by monitoring hydraulics through oil analysis. Contamination is the main cause of failure, typically water contamination or dirt ingression. All hydraulic systems have filters and regular monitoring is carried out for detecting early signs of contamination and resulting wear, as well as for determining the effectiveness of the filtration.

Tolerances in a hydraulic system are usually very tight. The clearances on actuators can be as small as 10 μm and the clearances on servo valves are regularly of the order of 40–80 μm, therefore particles greater than 4 μm can cause critical issues in hydraulic systems. There are various SAE guidelines, ISO codes, and ASTM Methods dedicated to measuring particles in hydraulic systems. A majority of these techniques or codes bin particles by concentration and size.

Producers of hydraulic systems will indicate the usage of particular ISO codes when evaluating system cleanliness. For example, producers might suggest the use of ISO code 18/16/13 for the actuator and valve, whereas ISO code 20/18/15 for the pump in the hydraulic system.

Another contaminant that is usually found in hydraulic systems is water. Water can cause corrosion and oxidize the hydraulic fluid. Normally, water contamination should be maintained less than 2500 ppm.

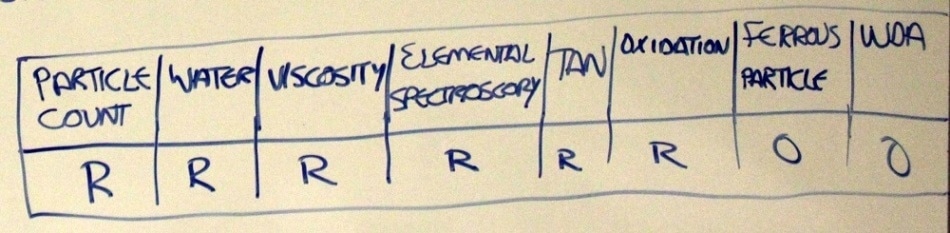

Key Parameters to Monitor

Particle Counting

The measure of the purity of a fluid is a crucial test for hydraulic systems. Servo valves have very tight tolerances and are subjected to jamming with improperly filtered fluid. All OEMs specify purity levels to ISO 4406, so often, regular particle counting is crucial. When counts are higher, it is important to know the cause.

Newer technologies, for example, LaserNet Fines, not only count particles and report to SAE AS 4059 or ISO 4406 but also offer more information to understand where the particles are originating from. Particle imaging allows the maintenance team to instantly see sand/dirt particles and also the level of ferrous debris that is contributing to the count. This level of detail enables smarter work orders to be created, concentrating on removing the root cause of the high counts.

Water Contamination

Globally, water is the most common liquid contaminant in power plants and always needs to be monitored. Excessive water in a system destroys the ability of a lubricant to separate opposing moving parts, enabling the occurrence of serious wear with resulting high frictional heat. For most hydraulic systems, water contamination should not surpass 0.25%. A number of new methodologies are available for detecting water contamination in lube oils, and on-site results compare extremely well with laboratory methods.

Kinematic Viscosity

Kinematic viscosity is the resistance of a fluid to flow under gravity. The most significant physical property of lubricant is viscosity. Lubricants must have appropriate flow characteristics for assuring that an adequate supply reaches lubricated parts at different operating temperatures. The viscosities of lubricants change based on their grade or classification, and also the degree of oxidation and contamination in service. Oil viscosity is supposed to increase over time and use, and loss of viscosity is regarded to be more severe than an increase. Innovative technologies make it easy to measure kinematic viscosity—solvent-free, low-volume systems are available that integrate usability with data logging capability.

Total Acid Number

Total acid number (TAN) refers to a titration method proposed for specifying the relative acidity in a lubricant. The acid number is used as a guide to follow the oxidative degeneration of an oil in service and is often referred to on OEM equipment or in lubricant supplier guides. Oil changes are regularly indicated when the TAN value attains a preset level for a given lubricant and application. A sudden increase in TAN would be demonstrative of abnormal operating conditions (for instance, overheating) that need investigation.

Elemental Spectroscopy

Elemental spectroscopy is a method to detect and quantify metallic elements in used oil as a result of contamination, wear, and additives. The oil sample is energized to make every element emit or absorb a quantifiable amount of energy, which signifies the concentration of elements in the oil. The results consider the concentration of all dissolved metals (from additive packages) and particulates. This test is the backbone for all off-site and on-site oil analysis tools, as it offers information on wear condition and machine contamination quite rapidly and correctly. Its major hindrance is that its particle detection efficiency is inadequate for particles in the size of 5 μm or more.

Oxidation by Infrared Analysis

Oxidation is a measure of the degradation byproducts in the hydraulic fluid. If oxidation becomes serious, the lubricant can corrode critical surfaces, as well as deposit silt or lacquer deposits at servo valves. Oxidation is directly proportional to the “oxidation number” being high. Conditions like varnishing, sludge deposits, sticky valves, lacquering, and filter plugging take place in systems with oxidation issues.

Wear Debris Analysis/Analytical Ferrography

Wear debris analysis (WDA) explains either a patch or an analytical method that separates magnetic wear particles from the oil and deposits them on a glass slide called as a ferrogram. Microscopic investigation of the patch or slide allows characterization of the wear mode and predictable sources of wear in the machine. This method is called analytical ferrography. It is a good indicator of abnormal non-ferrous and ferrous wear, yet it is generally only performed by a trained analyst.

This information has been sourced, reviewed and adapted from materials provided by AMETEK Spectro Scientific.

For more information on this source, please visit AMETEK Spectro Scientific.