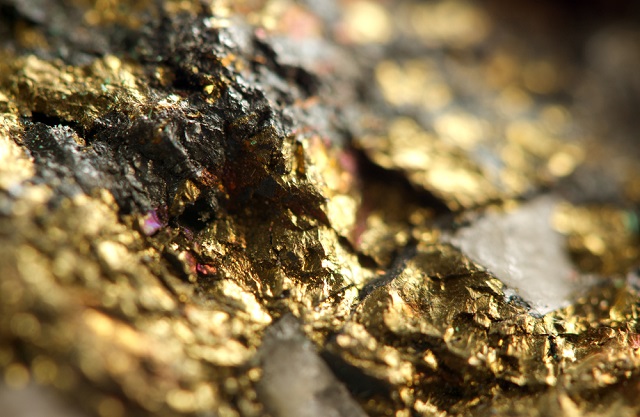

African Gold Group, Inc. is pleased to announce the results of metallurgical test work and provide an update on the progress of the feasibility study.

assistant | Shutterstock

METALLURGICAL UPDATE

The company completed additional metallurgical test work at Gekko Systems facilities in Ballarat and Bureau Veritas in Perth, Australia, as part of the Feasibility Study process. This work confirms the results established in test work completed in 2014. Overall metallurgical recovery of gold was found to be 80% using the flow sheet established in the previous work.

A 92 kg sample of ore, assaying 0.92 g/t, was initially washed (a process known as scrubbing) and then wet-screened over a 1.18mm screen. The screen oversize represents 20% of the mass, and contained 49% of the gold at a grade of 2.31 g/t. The screen undersize represented 80% of the feed, had a grade of 0.58 g/t. The screening process provided a significant upgrade of the oversize, which was then crushed to below 1.18mm, and combined with the gravity feed to the gravity concentration process.

The screen undersize was processed using hydro-cyclones to further remove fine material. The cyclone process resulted in the rejection of 81% of the cyclone feed into a low grade overflow slimes product at a grade of 0.09 g/t Au, representing only 6% of the feed gold.

This means that 94% of the contained gold is captured into 35% of the total feed tonnage in the pre-concentration step (scrubbing, screening and cycloning). This significant upgrade is consistent with previous testwork and demonstrates the simplicity of upgrading the grade of pre-concentrated ore by a factor of 2.7 times (i.e. from 0.92 g/t to 2.46 g/t Au) before further gravity processing.

Testwork completed to date on the gravity concentration on the combined crushed coarse ore and cyclone concentrates demonstrated that approximately 80% of the total contained gold can be concentrated into a mass yield of 5% of the total feed. Gold contained in this high grade (~33g/t Au), low cost and low mass concentrate can then be recovered using traditional cyanide leaching techniques.

Mr. Declan Franzmann, President and CEO of African Gold Group, commented, "yet again the results of pre-concentration test work show very significant mass rejection with relatively low loss of gold. The results of pre-concentration have been repeated three times on oxide ores from different locations and depths at Kobada, with very similar results each time. These results indicate that simple low cost processing techniques readily upgrade the Kobada ore types. It is this fact that results in high gold recovery with low processing costs."