Thermal analysis helps evaluate a material's physical attributes as a temperature function. Near the end of the nineteenth century, clays were among the first materials to be researched using thermal analysis. Thermal analysis techniques are currently used to assess various materials' physical and chemical qualities as a function of temperature and time.

Image Credit: Matt_Turner/Shutterstock.com

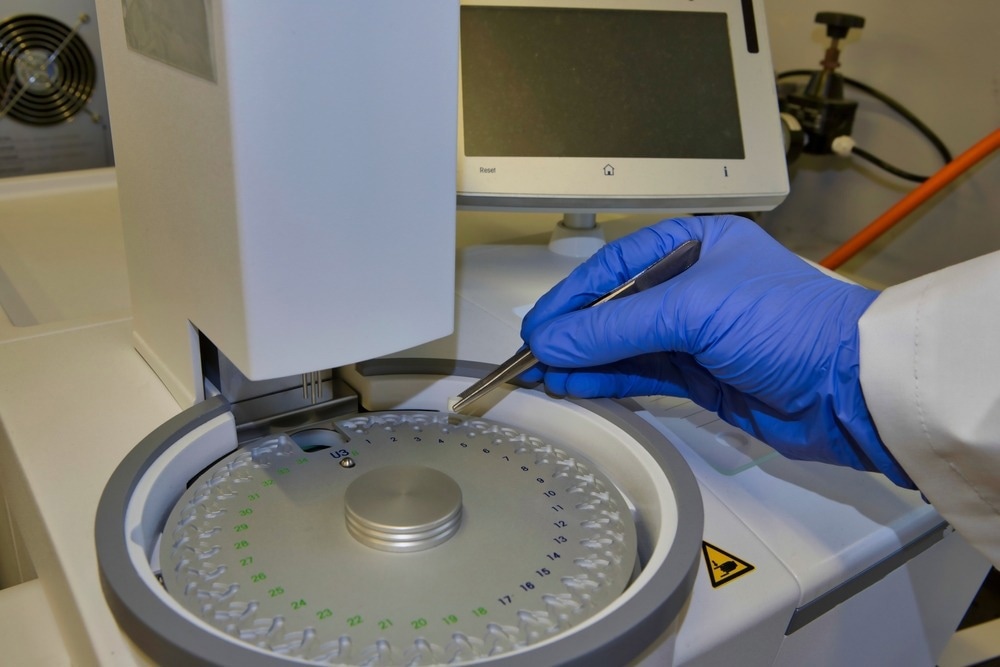

Several thermal analysis techniques are being used for specific purposes, including differential thermal analysis (DTA), differential scanning calorimetry (DSC), thermogravimetry (TG), dynamic mechanical analysis (DMA), and thermomechanical analysis (TMA).

Melting temperatures, glass transitions, the heat of fusion, crystallization, cure times, and specific heat are all determined using DSC. Conversely, TG is used to calculate percent moisture, percent ash, and decomposition. DMA is used to study modulus or viscosity, whereas TMA is used to determine thermal expansion and compression forces.

Thermal Analysis in Mining

In mining, the proximate coal and coke analysis is carried out using DSC or TG. Another application for these methods is the loss-on-ignition (LOI) test, a standard method for determining the carbon content of fly ash for coal-fired boilers.

LOI is established using a macro-TG or a muffle furnace and can be implemented in a single-step or a two-step manner. However, this method has limitations in the form of weight loss due to dehydration of calcium hydroxide or decarbonation of calcium carbonate.

DSC can be utilized to assess the solid phase transitions in ceramic materials and other minerals such as zeolites. DSC can also estimate the specific heat of rock and soil.

A study by Strzakowska used TG to conduct thermal analysis for testing timber combustibility used in mine supports. This study conducted TG and DTA tests on three powdered timber samples from an old mine using a Paulik-Paulik-Erdey derivatograph. It was observed that the weight loss in the timber samples occurred in the range of 240 °C and 440 °C, wherein the samples exhibited a 90% loss in total weight. It was determined that the wood timbers' ignition temperature and combustion times were impacted by the hygroscopic water content and the water content forming the molecular cellulose bonds.

Elemental Analysis

The thermal behavior of clay minerals can also relate to their crystalline structure using thermal analysis techniques.

By the late 1950s, DTA had become a prominent tool in clay mineral identification. However, by principle, DSC is superior to DTA as it determines the corresponding heat and the transformation temperature.

Nevertheless, the dehydroxylation energy during DSC depends on the type of bond. This drawback is overcome by TG, where the sample mass is the measured quantity.

The thermal analysis of clay minerals involves separating different kinds of water in the clay. Techniques such as sample-controlled thermal analysis (SCTA) can be used to determine clay mineral contents such as chlorite and talc as well as to characterize the minerals’ initial state to differentiate between identical mineral species. Moreover, the ability to control the dehydration rate at adequately low temperature and pressure gradients makes SCTA an effective testing method for highly homogenous samples as compared to the standard temperature-programmed heating.

Mine Refuge

The mine safety and health administration (MSHA) regulations for underground coal mines mandate the implementation of refuge alternatives (RAs) to maintain a breathable environment for at least 96 hours.

To prove that their RAs maintain the desired conditions, manufacturers are required to carry out heat/humidity testing.

Heat input devices are utilized in heat/humidity testing to simulate the metabolic heat of real miners. To model the heat input of real miners, the National Institute for Occupational Safety and Health (NIOSH) generated simulated miners (SMs) in 2012 to produce 117 W of metabolic heat input representing real miners.

The temperatures were measured using sensors such as resistance temperature detectors (RTDs) and thermocouples. Two-watt transducers were utilized per programmed variable autotransformer to gauge the heat input associated with heated water tanks (PVA) and SMs. To detect surface temperatures, ribbon-type, silicone-encapsulated Class A RTDs were attached to the RA.

The Future of Thermal Analysis in Mining

To summarize, thermal analysis techniques have multiple applications in mining and mining-related activities. TG and DSC can be used to determine coal and coke proximate analyses and rock and soil-specific heat. Other qualitative applications include the estimation of phase transitions in ceramics and zeolites, as well as mineral identification and characterization in clays.

Additional uses of thermal analysis include research in determining the combustibility of the timbers used in mines as well as investigations in controlling heat/humidity buildup in RA manufacturing. These studies further widen the scope of thermal analysis as a tool for assessing and preventing mine safety hazards.

References and Further Reading

D.S. Yantek, L. Yan, N.W. Damiano, M.A. Reyes, J.R. Srednicki. (2019) A test method for evaluating the thermal environment of underground coal mine refuge alternatives, Int J Min Sci Technol. May; 29(3): 343-355. DOI: 10.1016/j.ijmst.2019.01.004

Yan, L., Yantek, D., Bissert, P., Klein, M., In-mine experimental investigation of temperature rise and development of a validated thermal simulation model of a mobile refuge alternative, https://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/In-mine

Perkin Elmer (2020) Thermal and Elemental Analysis in Mining, Understanding Sample Composition. https://www.perkinelmer.com/library/thermal-and-elemental-analysis-in-mining.html; https://www.youtube.com/watch?v=hEGnwL82Ve4

E Strzakowska (2019) IOP Conf. Ser.: Earth Environ. Sci. 261 012049, https://iopscience.iop.org/article/10.1088/1755-1315/261/1/012049/pdf

F. Rouquerol, J. Rouquerol, P. Llewellyn. (2013) Handbook of Clay Science Vol. 5B, Thermal Analysis. https://ftp.idu.ac.id/wp-content/uploads/ebook/tdg/TERRAMECHANICS

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.