May 8 2020

American Lithium Corp., a top lithium exploration and development operator, reports that the ongoing metallurgical testing has yielded highly encouraging results.

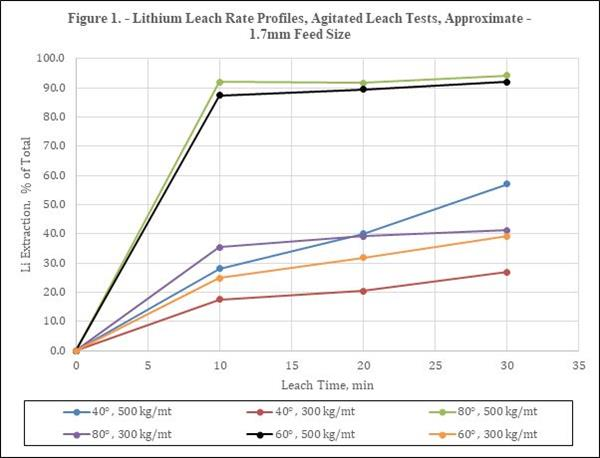

Lithium Leach Rate Profiles, Agitated Leach Tests, Approximate 1.7 mm Feed Size. Image Credit: American Lithium Corp.

Lithium Leach Rate Profiles, Agitated Leach Tests, Approximate 1.7 mm Feed Size. Image Credit: American Lithium Corp.

The metallurgical testing is being performed to recover lithium from the composite samples of reverse circulation drill cuttings obtained from American Lithium’s wholly owned TLC Lithium Claystone discovery located close to Tonopah in Nevada.

Sparks, Nevada-based McClelland Laboratories performed the metallurgical testing which showed that lithium recoveries of more than 90% were acquired in 10 minutes along with the leaching of sulfuric acid. Samples of reverse circulation drill cuttings were exposed to many extraction methods, such as acid curing, agitated leach, and counter-current agitated leach.

Along with the process assessment, the temperature of the leach solution was also analyzed. On the whole, the TLC Lithium Claystone was found to be consistently highly leachable across the projects with leach times matching quite favorably with other claystone projects.

Highlights

- Sulfuric acid leaching of the TLC mineralized samples yielded more than 90% lithium

- At a moderate leaching temperature of 60 °C, lithium was extracted from the mineralized material in just 30 minutes, with around 90% of this element extracted in less than 10 minutes

- Using an ambient temperature acid curing process, lithium extractions of around 90% were also demonstrated

- A counter-current leaching test revealed that the mineralized material can be utilized to counteract the sulfuric acid leaching solution, thus removing impurities like aluminum and iron from the solution and reducing the need for alkaline reagents.

American Lithium has improved the TLC project via rotary, core drilling, and reverse circulation since mid-2018, so as to establish high-grade lithium across a region of many square miles.

Apart from the drilling and further assay analysis, process and metallurgical testing has also been conducted. American Lithium has engaged Stantec Consulting Ltd. to finish a maiden resource lithium resource estimate for the TLC Lithium Claystone project. The company will shortly release the study results as well as a technical report thereon.

This preliminary metallurgical work, combined with the data and suggestions from Stantec Consulting’s work, will form the groundwork of sustained development at the TLC project.

Our excitement with TLC continues to build as the project gets further derisked at every stage. Very few sedimentary lithium deposits are like TLC. With high recovery rates, no deleterious elements, minimal overburden and a location minutes from major infrastructure, TLC is well positioned to be at the forefront of future lithium development.

Michael Kobler, CEO, American Lithium Corp.

Testing methodology and procedures for the TLC Lithium Claystone project are as follows.

Agitated Leaching

A composite sample of reverse circulation drill cuttings acquired from the TLC project (composite grade: 1,120 ppm Li) was subjected to a laboratory-scale agitation leach tests. The addition of sulfuric acid and slurry temperature was modified for a sequence of six tests.

Results demonstrated that at 60 °C and 80 °C leaching temperatures, lithium extractions of 92.1% and 94.2% were respectively obtained within just 30 minutes of leaching. Sulfuric acid equivalent to 500 kg/ton had to be utilized under these conditions.

Acid Cure Testing

Composite samples of assay pulp material, obtained from five different drill holes on the TLC Lithium Claystone project (composite grades: 1,060 to 1,270 ppm Li), were subjected to sulfuric acid cure tests. For each one of these tests, a sample weighing 0.5 kg was agglomerated with concentrated sulfuric acid and water. The agglomerates were cured for a period of 24 hours. These were then slurried in water (and agitated for around 5 minutes), filtered, and finally cleaned to recover the dissolved lithium.

Both curing and washing were performed at ambient temperatures. Lithium of 80.9% to 88.5% was extracted by following these processes, with the addition of 500 kg/ton of agglomeration sulfuric acid.

Counter-Current Agitated Leach Test

A composite sample obtained from drill hole TLC-1917 was subjected to a counter-current locked-cycle agitated leach test. The TLC-1917 drill hole had been pulverized to about 106 µm (composite grade: 1,320 ppm Li). This leach test involved numerous stages of agitated sulfuric acid leaching at 60 °C for 30 minutes.

After each leaching stage, slurry was filtered to isolate the pregnant leach solution (PLS) from solids. An additional sample material was used to contact the PLS, and the solids were washed or re-leached. This was performed in numerous locked-cycles to replicate a two-stage counter-current leach circuit with one stage of pre-leaching/solution neutralization and one stage of leaching.

Results demonstrated that it is possible to produce a neutralized PLS in a two-stage counter-current leach without using any alkaline reagents (for example, lime). The results also demonstrated that neutralizing the stage-2 leach solution by contacting it with un-leached material proved effective in removing aluminum and iron impurities from the leach solution before doing additional processing to recover lithium.

A highly agitated leach lithium extraction of 98.0% was obtained by adding 600 kg/ton of sulfuric acid. Further testing would be needed to improve the addition of acid in this process and to assess additional processing of the lithium-bearing leach solution.