Jan 15 2021

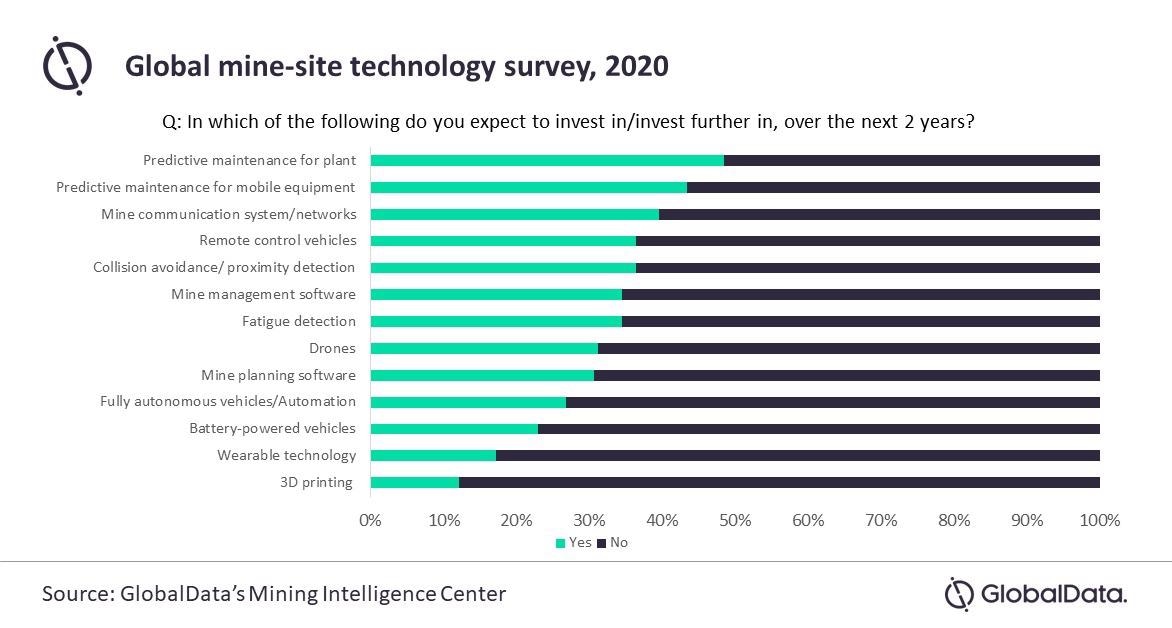

The drive to improve productivity and reduce downtime will lead to further investment by mining companies, large and small, in predictive maintenance for both plant and mobile equipment in the next two years, according to leading data and analytics company, GlobalData. A mine-site survey by the company revealed that, while over three quarters of mines had already made at least minor investments into predictive maintenance, 48% of miners surveyed expected to either invest in the technology for the first time or invest further in the coming two years. Further, 43% expected to invest in predictive maintenance for mobile machinery over the same period.

GlobalData’s report, ‘Global Mine-Site Technology Adoption Survey 2020’, notes that, across the regions studied, predictive maintenance adoption was highest overall in Australasia, and this region is expected to see the highest levels of investment over the next two years, followed by the Americas. The most widely adopted technologies were mine planning software, management software and communication systems, with a respective 89%, 86% and 83% of mines having already made at least minor investments in each of these areas.

David Kurtz, Director of Analysis, Mining and Construction at GlobalData commented: “Further investment in predictive maintenance is critical for mines looking to improve productivity and reduce expensive downtime. The ability of predictive maintenance to collect real-time data from sensors on equipment and use data analytics to detect potential problems before they lead to machine failure not only ensures continued productivity of critical operations, but saves money in parts and labour and can even extend the life of equipment, so the benefits of this technology are considerable.

The technology that has seen the highest increase in adoption over the last two years is drones. While 44% of mines had invested to some extent in drones in 2018, this share had risen to 64% by the end of 2020.