Capstone Mining Corp. ("Capstone" or the “Company”) announces it intends to advance the Cobalt Project at Santo Domingo in Region III, Chile, ("Santo Domingo" or the "Project") to Feasibility as described in the Santo Domingo Project, Region III, Chile NI 43-101 Technical Report and Preliminary Economic Assessment1 (the “Technical Report” or “PEA”). The production of battery-grade cobalt sulphate at Santo Domingo is expected to significantly add to the robust copper-iron-gold project and maximizes the recovery of future facing metals from this rich resource.

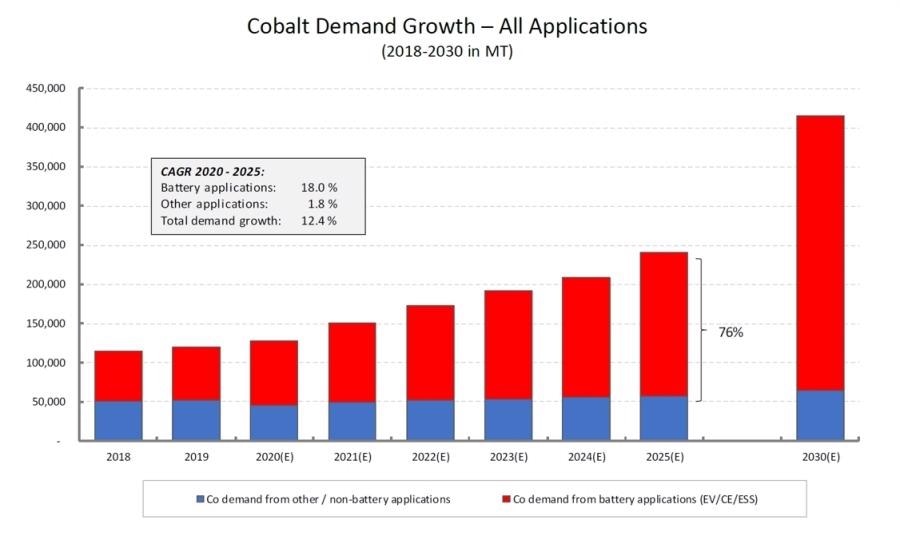

Figure 1. Cobalt Demand Growth – All Applications (2018-2030 in metric tonnes). By 2025, an estimated 184,000 tonnes of cobalt (or 76% of total cobalt demand) is needed in Li-ion batteries, of which 118,000 tonnes is required for various EV applications. Image Credit: Darton Commodities Ltd. estimates

Figure 1. Cobalt Demand Growth – All Applications (2018-2030 in metric tonnes). By 2025, an estimated 184,000 tonnes of cobalt (or 76% of total cobalt demand) is needed in Li-ion batteries, of which 118,000 tonnes is required for various EV applications. Image Credit: Darton Commodities Ltd. estimates

Darren Pylot, Capstone President and CEO said, “Capstone has an incredible opportunity to produce ethically-sourced battery-grade cobalt sulphate from Santo Domingo’s future copper-iron tailings stream. The process is a series of conventional steps, with below zero costs given significant by-product credits.”

“The potential of cobalt production in Chile has been underappreciated for decades while copper and, recently, lithium have been the main focus of investment. Although this market is small, projections for demand growth suggest that it could triple in size by 2030 mainly due to the development of electromobility. As the chemical properties of cobalt extends the life of rechargeable lithium batteries used in electric vehicles, we are seeing a significant boost to exploration and extraction activity. Capstone’s plans for a cobalt feasibility study at Santo Domingo could represent a great step forward and an example of Chile’s potential to become an important world producer.” said Edgar Blanco, Chile’s mining ministry undersecretary.

The santo domingo advantage in the global cobalt supply landscape2

- Downstream cobalt users are actively seeking ethical supply to meet future demand needs and Chile is one of the best mining jurisdictions in the world.

- In 2020, an estimated 71% of the 133,000 tonnes of cobalt produced globally originated from the Democratic Republic of Congo (DRC) and the majority of this was shipped to China, the leading importer of mined cobalt and exporter of refined cobalt.

- Global cobalt sulphate production in 2020 is estimated at 43,000 tonnes of cobalt contained. Of this, greater than 85% was produced in China and greater than 90% originated from DRC intermediates.

- By 2025, an estimated 140,000 tonnes of cobalt contained in cobalt sulphate will be required for lithium-ion (Li-ion) batteries.

- Cobalt contained in sulphate currently sells at a premium over the cobalt metal benchmark price3.

- The bulk of global cobalt sulphate production is dependent on refining third-party feedstock imported from other countries. The majority of cobalt sulphate producers are currently processing feed that is priced at around 93-94% of the cobalt metal benchmark price.

- Santo Domingo’s PEA estimated costs of -$4 per pound (net of by-products in cobalt operation) positions it to be a unique, fully integrated producer of battery-grade cobalt sulphate4.

- Santo Domingo will be the only cobalt sulphate project in the Americas not dependent on third-party DRC feed5.

- Santo Domingo’s cobalt processing capacity could supply enough battery-grade material for more than 500,000 electric vehicles (EV’s) annually6.

Mr. Pylot added, “A cobalt operation at Santo Domingo would unlock Chile’s vast potential for this critical metal and it is exciting that Capstone is leading this vision. The selection of a strategic partner due later this year, will accelerate this unique project to recover a future-facing, green metal from a waste stream, a plan that I’m set on making a reality.”

Table 1 and Table 2 outline the top 10 cobalt miners and refiners outside of the DRC and top three cobalt projects to come online within the next five years.

Cobalt sulphate demand growth

According to Darton’s recently published 2020-2021 Cobalt Market Review, Nickel Cobalt Manganese (NCM) is to remain the dominant cathode chemistry in EV batteries and cobalt sulphate is the prime ingredient for NCM precursor materials. By 2025, an estimated 184,000 tonnes of cobalt (or 76% of total cobalt demand) is needed in Li-ion batteries, of which 118,000 tonnes is required for various EV applications. Refer to Figure 1 for Darton’s Cobalt Demand forecast.

Expert hire to lead cobalt feasibility work at santo domingo

Romke Kuyvenhoven joined Capstone in February 2021 and is leading the cobalt feasibility work and overall metallurgical strategy for Santo Domingo. She has a M.Sc. in Mining Engineering from Delft University of Technology in The Netherlands and a Degree in Geo-Mining-Metallurgy from the Universidad de Chile. Previously, Romke worked at the Sustainable Minerals Institute in Santiago, where one of her focus areas was the characterization and metallurgical assessment of IOCG ores in Chile’s Atacama Region, where Santo Domingo is located. She is co-author on several recent international publications related to cobalt and was also the technical lead of the First International Cobalt Workshop in November 2018 in Santiago. As an independent consultant and formally registered QP, she has been involved in several NI 43-101 based due diligence studies and has acted as geometallurgical consultant for international financial institutions involved in these studies of Chilean mineral properties.

Dr. Albert Garcia, Ph.D., PE, Capstone’s Vice President of Projects commented, “I am very pleased to announce that we have hired Romke Kuyvenhoven as her experience in IOCG deposits and cobalt metallurgy is invaluable. Santo Domingo benefits from simple metallurgy and as it relates to cobalt recovery, means that we can recover nearly 80% of the cobalt contained in run-of-mine ore to refined battery-grade cobalt sulphate product that sells for a premium. Costs will be amongst the lowest in the world at negative $4 per pound given the by-product credits in the cobalt process in the form of increased copper recovery, sulphuric acid production and energy generation.”

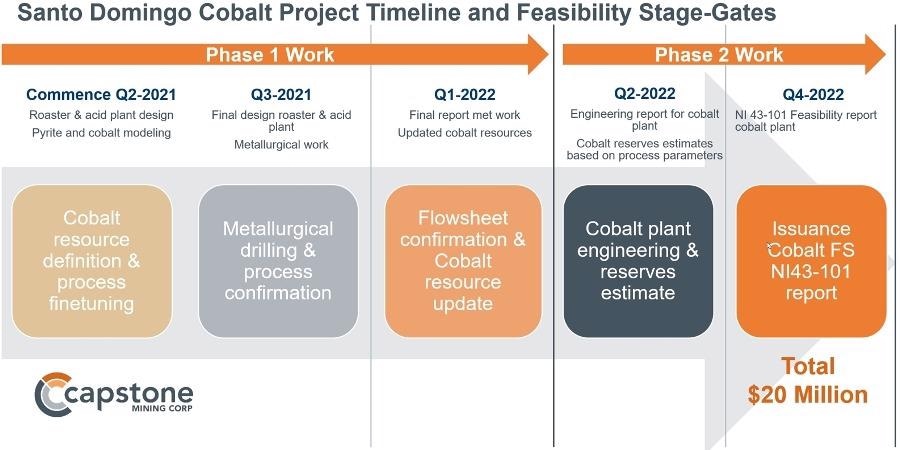

Santo domingo cobalt project timeline & feasibility stage-gates

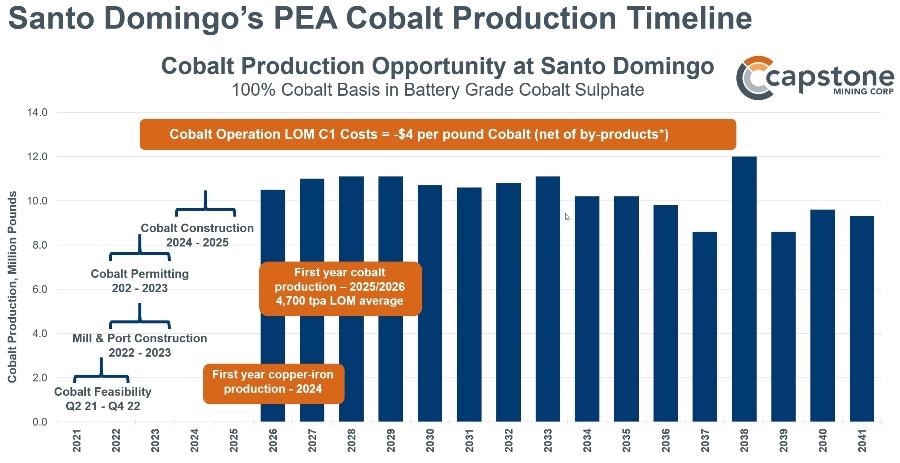

The $20 million work program will consist of two phases and several stage gates as outlined in Figure 2. Following the Phase 1 work program in Q1-2022, Capstone will provide an update to the market on final met work, final process design and updated cobalt resources. The feasibility report is expected by Q4 2022 with construction to start in 2023 or 2024 following permitting. The integration of the cobalt project with the copper-iron concentrator has been designed so that, if necessary, pyrite-cobalt concentrate can be safely stored in a lined, wet pond for two years, allowing for the cobalt plant to be built later than the mill. Figure 3 illustrates key pre-production milestones and expected life of mine cobalt production anticipated to commence by 2025 or 2026.

Figure 2. Santo Domingo Cobalt Project Timeline and Feasibility Stage-Gates. Image Credit: Darton Commodities Ltd. estimates

Figure 3. Santo Domingo PEA Cobalt Production Timeline. Key pre-production milestones and expected life of mine cobalt production anticipated to commence by 2025 or 2026. Image Credit: Darton Commodities Ltd. estimates

Cobalt process is a series of conventional metallurgical steps

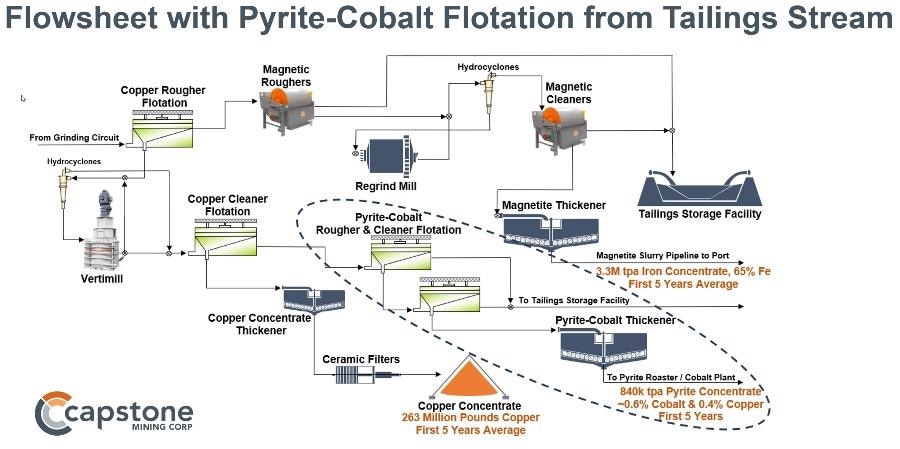

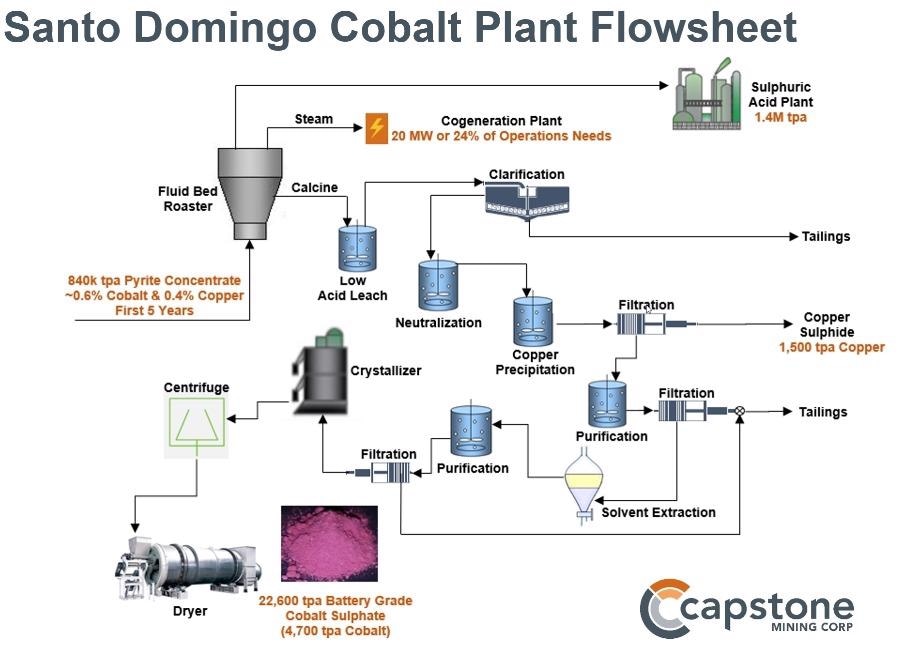

Capstone’s concept for cobalt recovery is based on its bond with pyrite, which is concentrated by preferential flotation on a tailings stream. Approximately 840,000 tonnes per year of pyrite containing 0.6% cobalt and 0.4% copper is expected to be recovered at this step. The concentrate is fed through a five-stage process consisting of roasting, leaching, copper precipitation, cobalt solvent extraction and crystallization to yield battery-grade cobalt sulfate heptahydrate. Recovery of cobalt from pyrite concentrate is expected to be approximately 90% at very low cost due to significant by-products from increased copper recovery, sulfuric acid production and energy generation. The flowsheets are simple and incorporate a series of conventional technologies that are used extensively in the mining industry, as shown in Figure 4 and Figure 5. The Santo Domingo concentrator is expected to commence construction in late 2021, with first year of operation in 2024.

Figure 4. illustrates the Concentrator PEA flowsheet: Santo Domingo Concentrator expected first year of operation in 2024. The flowsheet is simple and uses a series of conventional technologies that are used extensively in the mining industry. Image Credit: Darton Commodities Ltd. estimates

Figure 5. illustrates the PEA Cobalt Plant flowsheet. Santo Domingo cobalt operation expected first year of operation in 2025 or 2026. Image Credit: Darton Commodities Ltd. estimates