Red Pine Exploration Inc., a Canada-based precious metals explorer, provided an update on its 2022 Phase 1 drilling campaign which is advancing quicker and with higher efficiency than previously thought.

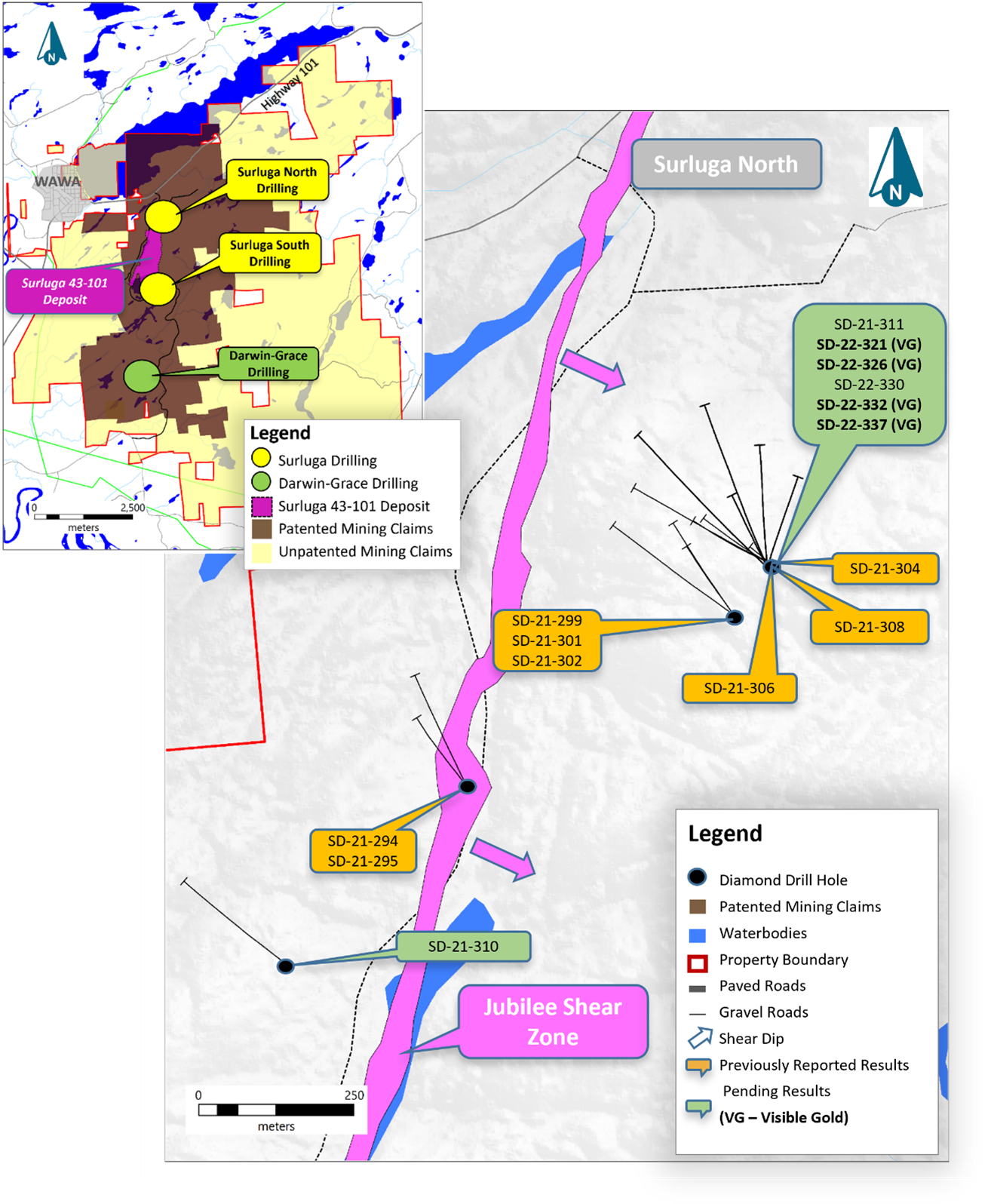

2021 and 2022 Surluga North Drilling. Image Credit: Red Pine Exploration Inc.

2021 and 2022 Surluga North Drilling. Image Credit: Red Pine Exploration Inc.

- In the first two months of 2022, the program has completed more than 7,680 m of drilling, or roughly 30% of the 25,000 m scheduled from period January to July 2022.

- Drilling has been concentrated on resource expansion targets in the Surluga North and South area and has begun drilling on the Grace-Darwin target. This is the first blue sky target within the defined program.

- Visual gold has been found in 6 of the 12 holes (assays pending) completed at the Surluga North, South, and in three holes in the Darwin-Grace targets.

- Currently, the Company has 1,203 assays pending at the laboratory. This represents 32 holes that have either not been released or have partially been released. Assays from the Phase 1 program are anticipated to be received this month and continue thereafter in a regular manner.

We remain encouraged with our focused and sustained drilling program below the existing Surluga and Minto Mine resource, validating our targeted approach. In the Darwin-Grace Mine area, our current drilling has considerably expanded the footprint of the mineralized systems associated with the historic Darwin-Grace Mine.

Quentin Yarie, President and CEO, Red Pine Exploration Inc.

Yarie continued, “We have indications that the former mine is located at the intersection of at least three different shear zones, and we have observed indicators of gold mineralization in those three structures, including under the historic Darwin-Grace mine.”

We have increased our workforce to expedite processing of core. We have begun prioritizing our core logging within our key zones of interest, with shipping of samples to the lab twice a week to expedite the sample positioning into the labs queue,” added Yarie.

On-Site Quality Assurance/Quality Control (“QA/QC”) Measures

Drill core samples were transmitted in security sealed bags for analyses at Actlabs in Ancaster, Ontario. Separate samples were labeled, positioned in plastic sample bags and sealed. Groups of samples were then positioned into durable rice bags and shipped. The samples’ residual coarse reject portions stay in storage if additional work or verification is required.

Red Pine has launched a quality-control scheme to follow best practices in the sampling and analysis of drill core. As a part of its QA/QC program, Red Pine implants external gold standards (low to high grade) and blanks every 20 samples as well as random standards, duplicates and blanks.