Wesdome Gold Mines Ltd. has disclosed the findings from the continuous surface and underground exploration drilling initiative at the Eagle River Mine, which is entirely owned by the company and located in Wawa, Ontario.

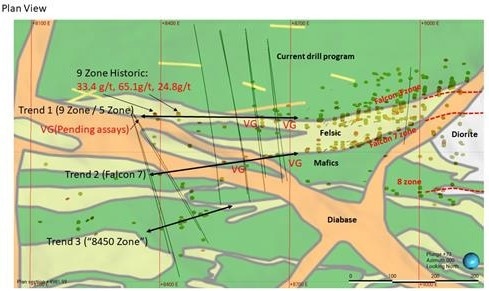

Plan View of Current Drill Program. Image Credit: Wesdome Gold Mines.

Plan View of Current Drill Program. Image Credit: Wesdome Gold Mines.

The initial surface drilling conducted to the west of the mine diorite has yielded high-grade results within a 200 m proximity from the surface. Furthermore, the first underground hole, positioned 750 m down plunge, has also encountered mineralization similar to the surface findings. The key highlights from the recent results:

In the volcanic rocks to the west of the existing mine infrastructure, the initial surface drilling has shown promising results.

- Hole ERS-2023-001: 64.4 g/t Au over 0.4 m core length (64.4 g/t Au capped, 0.4 m true width)

- Hole ERS-2023-005: 7.0 g/t Au over 2.6 m core length (7.0 g/t Au capped, 2.2 m true width)

Underground drilling has also revealed a continuity of mineralization directly down plunge within the volcanic rocks.

- Hole 857-E02: 33.4 g/t Au over 0.4 m core length (within 6.4 g/t Au capped over 1.5 m true width)

All assay results have been limited to a maximum of 125 grams per ton of gold (g/t Au). The true widths of the mineralization are approximated using a 3D model construction.

The results of the initial surface and underground drilling suggests the potential of a parallel structure in the volcanic rocks west of the mine diorite, with results consistent with those seen in early drilling at the Falcon 7 Zone in 2019. Not only are these results near existing mine infrastructure, but they demonstrate potential for high grade mineralization in a rock type that has seen limited drilling to date.

Ms Anthea Bath, President and CEO, Wesdome Gold Mines Ltd.

Ms Anthea Bath adds, “This drilling is part of a renewed strategy focused on the upper areas of the mine and will include the assessment of previously mined areas. By developing and optimizing the strategic mine plan from these additional resources, this could add incremental tonnes for processing at our underutilized mill.”

Additionally at Eagle River, drilling continues to confirm the geometry, spatial continuity and high grades of the 300 East Zone at depth. This suggests that many other similar parallel zones, namely the 8 and 7 Zones, have the same potential to continue at depth.

Ms Anthea Bath, President and CEO, Wesdome Gold Mines Ltd.

Further Technical Details

In the initial part of this year, an updated 3D geologic model was developed to the west of the mine diorite with the aim of providing guidance for exploration efforts. The interpretation indicates that the gold mineralization is situated within an intermediate volcaniclastic rock formation.

These volcaniclastic rocks are considered to be more brittle and serve as a more favorable host for gold mineralization compared to the relatively ductile mafic volcanic flow units that surround them.

Exploratory drilling activities, both on the surface and underground, commenced in July with the objective of uncovering additional gold mineralization in this region. These efforts have resulted in the discovery of well-altered quartz veins containing visible gold (VG) across narrow widths.

Furthermore, recent drill holes have intercepted mineralization in the hanging wall of the Falcon 7 zone, suggesting the potential presence of parallel or folded limbs. Additional plunging shoots of gold mineralization have been identified further to the west in close proximity to the historical 9 zone. It seems that these gold shoots exhibit a comparable periodicity to the gold mineralization found in the mine diorite.

Technical Disclosure

The sampling and assay data derived from the drill core are subjected to rigorous monitoring by implementing a quality assurance-quality control (QA-QC) program, which adheres to industry best practices. Samples from underground drilling are securely transported in sealed bags to the Eagle River Mine assay office in Wawa, Ontario, for analysis.

The gold content is determined using the standard fire assay technique with a gravimetric finish. Wesdome incorporates blank samples and certified reference standards into the sample sequence to ensure and maintain quality control at the laboratory.

For a more comprehensive understanding of the QA/QC procedure, additional details can be found in the 2022 Technical Report, which was submitted to SEDAR on April 22, 2022.