Jun 10 2020

Pershimex Resources Corporation has reported the extraction of its first dore (32.6 g) generated from a ton of mineralized material from the surface pillar of the former Pershing-Manitou mine, situated on its Courville Property.

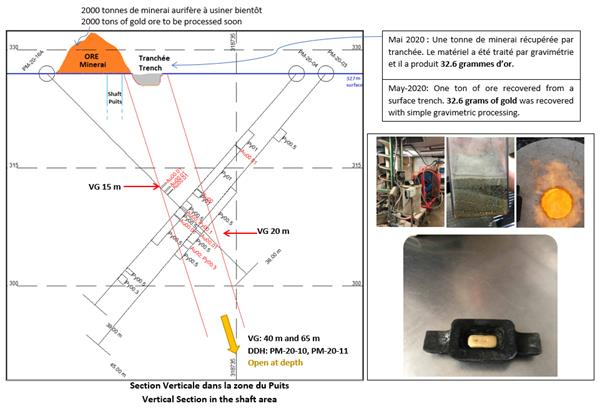

Vertical Section in the shaft area. Image Credit: Pershimex Resources.

Vertical Section in the shaft area. Image Credit: Pershimex Resources.

The surface trench from where the mineralized material was obtained and utilized to generate the Pershimex’s first ounce of gold was finished this spring. The mineralized material selected from the surface trench includes centimetric quartz veinlets and veins mineralized in pyrite and coarse native gold grains accumulated in a diorite.

The 1000 kg material was crushed and coarsely grounded to <1000 μm. Thus, the material released was full of spiral and Wilfley’s table. Rough grinding with just gravimetric concentration enabled casting of 32.6 g of gold.

The 1000-kg sample illustrated the ease of gold recovery by the gravimetric technique. Also, it is feasible to verify whether high grades exist on the surface apart from being retrievable easily and economically, particularly in the present context of gold price.

Previous winter, Pershimex carried out two diamond drill holes (PM-20-04 and PM 20-16A) directly under the trench at vertical depths of 15 and 20 m. Both the holes are situated at the heart of the surface pillar of the former Pershing-Manitou mine and intersected metric mineralization intersections including various coarse visible gold grains.

A point to note is that the regular process of operations restarted at the assay laboratory after the work was stopped due to the COVID-19 pandemic. It is expected that the final drilling results will be available shortly.

The pouring of this first ounce of gold from a ton of mineralized material from the surface pillar of the former Pershing-Manitou mine is undoubtedly an important step in the continuity of our project.

Robert Gagnon, President and CEO, Pershimex Resources Corporation

Gagnon continued, “By the same, we validate the ease of recovering the gold on our Courville property. This confirms the relevance of our phase 1, for sending 2,000 tons in a mill. The Company is expected to conclude an agreement with a milling plant in the Val-d’Or area to process the mineralized material pile in the near term.”